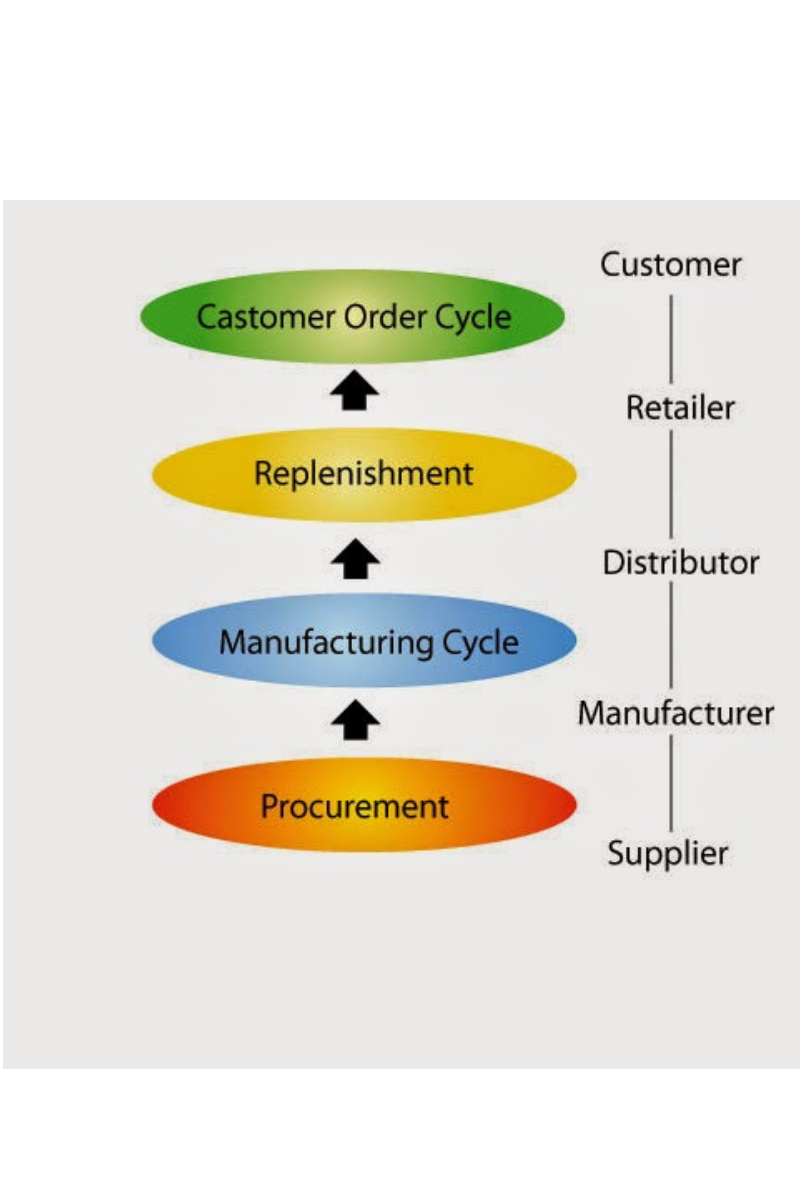

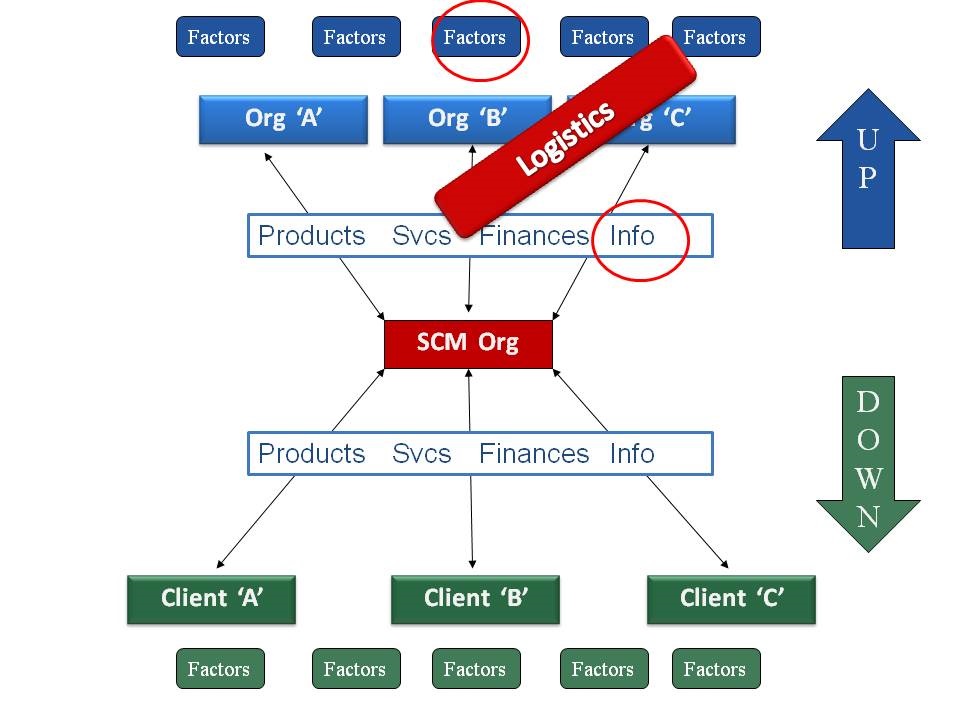

The processes in a Supply Chain are usually divided into a series of cycles, each performed in the interface between two interrelated successive stages of a Supply Chain. Sub-processes in each Supply Chain Process Cycle I.e., each cycle comprises six sub-processes, supplier stage markets a product, buyer stage places order, supplier stage receives order, supplier stage supplies order, buyer stage receives supply, buyer returns reverse flows to a supplier or the third party.

Archives

A discussion about Unilever’s Supply Chain Management : A Case Study |

Unilever’s vast operations require a robust SCM to manage the flow of materials across continents and the company is committed to sustainable sourcing practices. Unilever’s supply chain management includes advanced technologies and lean manufacturing principles to optimize production and minimize waste. The company also uses a sophisticated logistics network for timely delivery of products and is embracing digital technologies to enhance supply chain visibility and efficiency, including the use of IoT sensors, AI-powered analytics, and blockchain. Unilever is a pioneer in sustainable practices, such as palm oil sourcing and achieving zero waste to landfill status in many factories, showing its commitment to environmental sustainability. Suppliers who meet Unilever’s criteria for climate leadership can sign the Unilever Climate Promise to demonstrate their commitment to sustainability.

How supply chain planning works: A discussion in brief |

The uncertain nature of the customer demand need to take into consideration by generating the production plan and in particular the production quantities, to meet uncertain customer demand in the best way possible and maximize the profit, by minimizing production costs. Aggregate planning is a process by which a company decides about their ideal levels of capacity, production, inventory, stock-out situations, pricing, subcontracting, etc. Production planning, is the correct placement of production orders concerning place, or region, of production, and time scheduling and sequencing of production orders. The parameters are usually production rate, workforce, overtime, machine capacity level, subcontracting, backlog, and inventory on hand. The amount of overtime production planned is a parameter for aggregate production planning. Production planning for fashion apparel products has to cope with demand uncertainties. Collaborative forecasts created by various enterprises are an important input in aggregate supply chain planning. However, at the time of generating the production plan, the predicted customer demands are largely uncertain.

What is International export and outbound logistics of goods? |

In the international export trade, goods and services, i.e., international export and outbound logistics, goods and services are sold and shipped out of the jurisdiction of the country and customs authorities. While exporting to developed countries, Bangladesh gets some tariff facilities. It is nothing but helping the developing countries in export trade and industrialization, on the other hand, they regulate some products to enter their country at a lower price. Currently, Bangladesh is enjoying tariff-free market access for 90 percent to 100 percent of products in all the developed countries except the United States. Tariff-free and low-tariff market access facilities in developed and some developing countries immensely benefited Bangladesh. Bangladesh High Commissioner to Ottawa wrote that quality of Bangladesh’s apparel products as well as the efficient supply-chain mechanism has largely contributed to doubling bilateral trade in a decade.

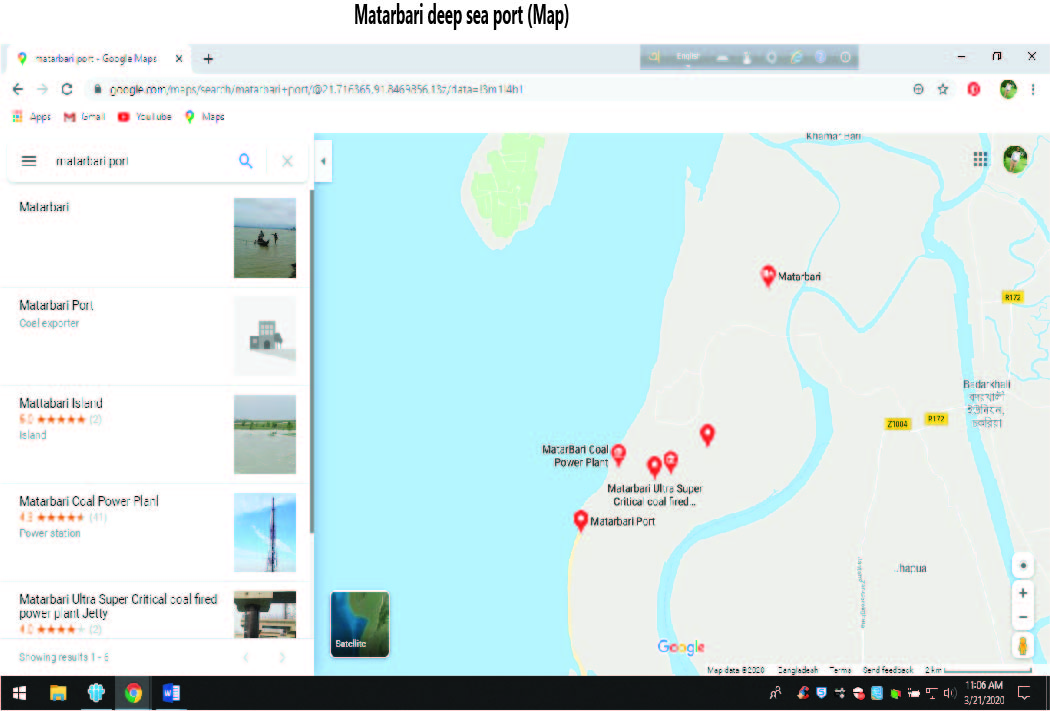

About the Matarbari deep sea port: A Supply Chain Management perspective |

To ensure load unload of deep draft vessels the Matarbari port is essential for Bangladesh and adjacent countries and areas. The Matarbari deep sea port has a 16m depth that will help 16m draft vessels to unload their cargo at the terminal. At deep sea, currently mother vessels unload the cargo at feeder vessel and they carry the cargo to the Chittagong port. The present seaports (Chattogram sea port and Mongla sea port) of the country do not have the capacity to handle huge containers and vessels and the building of a deep sea port is the only solution. Chittagong port can’t load unload from more than 9.5 meter vessels.

Supply Chain Management Career: A Discussion in general

In a case study, based on USA-based companies, first-level management is of about 0-4 years.To understand the supply chain management career we can remind ourselves about the example of leaf cutter ants.But Supply Chain Managers attempt and optimize the steps to produce the necessary amount of product and deliver the product to the end user at the right time when consumers need it.APICS, Founded in 1957 as American Production and Inventory Control Society and re-branded as The Association for Supply Chain Management in 2018, launched their CSCP (Certified Supply Chain Professional) programme in 2006. Institute for Supply Management, Founded in 1915 as the National Association of Purchasing Agents, launched its CPSM Certified Professional in Supply Management programme in 2008. Council of Supply Chain Management Professionals, Founded in 1963 as the Council of Logistics Management, launched their SCPro programme in 2011.For Supply Chain Management roles, “Process Engineer”, and “Supply Chain Analyst”.For Supply Chain Systems Manager roles, “ Supply Chain Manager”, Vice President, Supply Chain Management”.For Sales and Customer Service roles, “Account Specialist”/ “Customer Service”, “Customer Service Manager”, “Account Manager/Supply Chain Sales” etc.

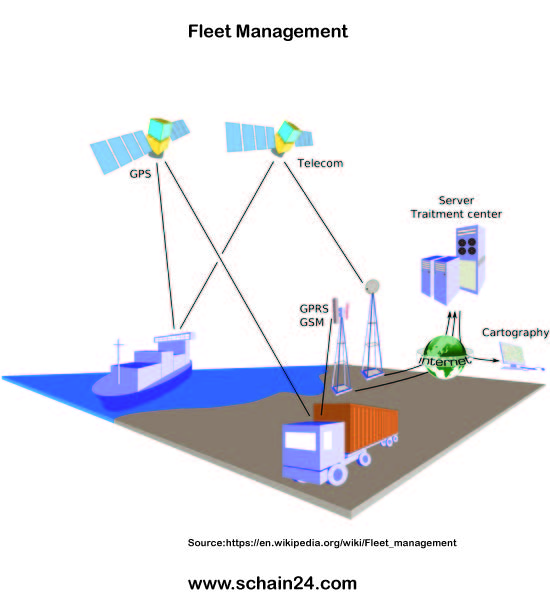

Best Practices for Efficient Fleet Maintenance Scheduling

Introduction The fleet functions like an orchestra, where even one malfunctioning piece of equipment can disrupt harmony and affect performance. That is why fleet managers place such great importance on developing robust maintenance schedules. Proper scheduling unlocks new levels of efficiency, keeps down fleet management costs, and improves the lifespan of crucial machinery. Here are some best practices to […]