The rise of e-commerce has brought significant changes to the global economy, altering industries and consumer behavior. However, it has also presented challenges and opportunities for supply chain management. E-commerce has led to an increase in demand for quick order fulfillment, requiring more sophisticated logistics networks and faster delivery services. Inventory management has become more complex, with the need for real-time visibility and accurate demand forecasting to prevent stockouts and overstocking. Achieving transparency across the supply chain is crucial for accurate and on-time order fulfillment, while managing returns efficiently is important for customer satisfaction and cost control. Integrating supply chain management with e-commerce platforms allows companies to provide a seamless shopping experience with real-time tracking information and multiple delivery options. An agile and responsive supply chain enables companies to adapt quickly to changes in customer demand and external disruptions, ensuring high levels of customer satisfaction and loyalty. By adopting automation and digital technologies, companies can lower costs, increase efficiency, and gain a competitive edge in the fast-paced e-commerce environment. So, there are Ecommerce challenges and opportunities for supply chain management.

Category: Supply Chain Management

How to enhance supply chain management efficiency using AI technology? |

AI uses historical sales, market trends, weather, and social media to predict demand with higher accuracy so that it enhances supply chain management efficiency. Machine learning models detect patterns and seasonal trends, reducing overstock and stockouts. AI algorithms aid in route planning, fleet management, and delivery

scheduling, reducing transportation costs. AI-powered systems manage factory floors and production lines more efficiently, enhancing capabilities and reducing machine downtime. Robotic Process Automation and AI automate repetitive supply chain tasks, including order processing, invoicing, vendor communication, and procurement workflows.AI enhances supplier selection, risk assessment, and collaboration, with improvements in risk prediction, AI-powered supplier scorecards, and automated negotiation.AI and computer vision enable

smart warehousing, with AI-driven robots for picking and packing, real-time inventory tracking, and optimized layout and storage space. AI chatbots and virtual agents ensure a responsive and proactive customer service experience. AI-based analytics platforms provide real-time dashboards and predictive insights, scenario modeling for disruptions, cost-to-serve analytics, and recommendation systems for best supplier and logistics choices.

How Does Semiconductor Technology Impact the Global Supply Chain?

The industry`s annual semiconductor sales revenue has since grown to over $481 billion, as of 2018. In 2021, the sales of semiconductors reached a record $555.9 billion, up 26.2 percent with sales in China reaching $192.5 billion, according to the Semiconductor Industry Association. To make the semiconductor supply chain sustainable, companies need to focus on environmental processes, social practices, and the economy. In order to generate a sustainable future, supply chains should work to improve the manufacturing process and quality, reduce the environmental impact, and protect labor rights. Take time to learn about semiconductor supply chains so you are informed of their impact on the technological industry. As strains between China and the US worsen over Taiwan, and countries across the world reassess connections with Russia following its war In Ukraine, efforts to de-risk chip technologies are causing a realignment of supply chains according to geopolitical relations.

What are The Impacts of RobotMeta on Supply Chain Management: A Case Study

Abstract RobotMeta is a flexible industrial robot company that specializes in welding applications. Their robots are user-friendly, allowing small and medium-sized enterprises (SMEs) to integrate robotic solutions into their operations. They offer ready-to-weld packages including synergic or pulse (MIG/MAG) systems, which are easy to set up and use. RobotMeta’s robotic welding system reduces the time required for welding operations, enabling […]

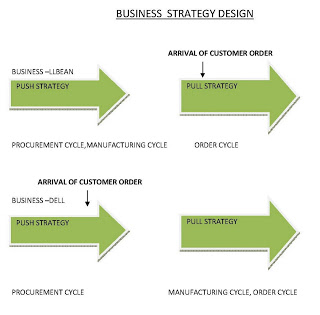

About the Push-Pull view of Supply Chain Process ।

The Supply Chain processes start cases with the express market needs, which pushes research and development, which pushes production and production pushes marketing to meet the already expressed demand. If the customer orders are speculative and order execution is initiated based on anticipation, then the Supply Chain process is under the “Push” process. Demand is not filled from finished product inventory but from production. In Logistic Chains or supply chains, the stages are operating normally in both a “Push” and “Pull” manner. The Supply Chain processes start sometimes with research and development, which pushes Production. The execution of the Supply Chain process is reactive to customer demand according to the Push-Pull view of Supply Chain.

How to Explain Toyota’s Financial Management Philosophy? : A Case Study |

Toyota’s financial management philosophy is conservative, with a low debt-to-equity ratio and a focus on retained earnings.The company’s ambition is carefully calculated and backed by a strong equity base. Toyota’s production philosophy, the Toyota Production System (TPS), is a culture of efficiency and continuous improvement. Toyota’s production philosophy, the Toyota Production System (TPS), is a culture of efficiency and continuous improvement. Principles like just-in-time manufacturing and waste minimization keep production costs low and productivity high. The concept of “Kaizen,” or continuous improvement, empowers employees to find ways to enhance efficiency. Toyota is known for its long-term thinking, particularly in research and development (R&D).

The company has consistently allocated billions of dollars annually toward R&D, focusing on areas that will define the future of mobility. Toyota employs sophisticated risk management strategies to mitigate challenges such as currency fluctuations, trade barriers, and geopolitical instability. The company uses financial instruments to lock in favorable exchange rates and geographical diversification to cushion the blow from localized downturns or regional policy changes. Toyota consistently generates strong operating cash flow, allowing it to reinvest in the business, pay dividends, and maintain a healthy balance sheet. The company holds significant cash reserves to safeguard the company against unforeseen challenges. Despite its conservative financial management, Toyota maintains a stable dividend policy and initiated share buyback programs to enhance shareholder value. The company’s returns, combined with strategic reinvestment and prudent financial controls, make it an attractive proposition for long-term investors. Toyota has embraced environmental, social, and governance (ESG) principles as part of its financial and corporate strategy.

Unveiling Amazon’s Digital Supply Chain Strategies: A Case Study

Abstract Amazon’s digital supply chain is a technological marvel, integrating software and hardware to connect every link of the chain, from suppliers to customers. It uses advanced algorithms and machine learning to predict stock needs with precision, ensuring products are available when customers want them. Amazon’s fulfillment centers feature robots and human workers, enhancing efficiency and reducing mistakes. Amazon […]