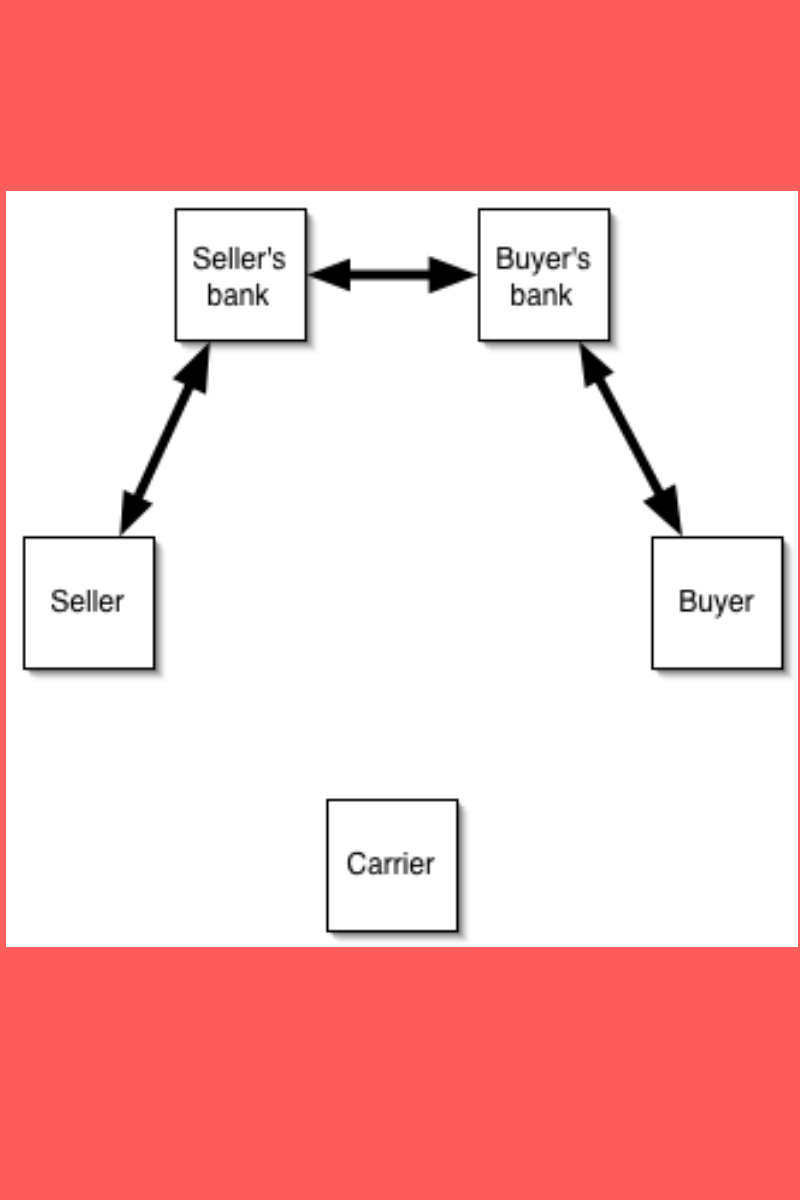

A letter of credit(LC) is also named a documentary credit(DC) in globalized international trade. In recent times blockchain technology is utilized by banks regarding the formulation of letters of credit. The ICC regulates market practices (Documentary Credit 600) in this regard. These include the advising bank that will give the documentary credit to the beneficiary or their nominated bank and provide their nominated bank with any amendments to the letter of credit. A certain percentage of the letter of credit value is retained by the bank for security purposes. Blockchain technology is available for the letter of credit procedure and trade finance is related to it. Commerce and international trade finance include products such as issuing letters of credit, indemnifying Bills of Lading, etc. Although the letter of credit was created in the old world methods managing the shipping of goods and related accommodations. But there is a great potential to supersede these paper processes with digitized operations utilizing blockchain technology. International trade requires a number of participants to interact with one another i.e., the exporters, importers, banks, shipping companies, port-related entities, and customs. Trade finance in supply chain management(SCM) includes products such as lending, issuing letters of credit, factoring, export credit, and indemnification.

Category: Supply Chain Management

Post Covid-19 Supply Chains: A Brief Discussion

The U.S.-China trade war and the Covid-19 crisis have prompted manufacturers worldwide to reassess their supply chains, focusing on increasing domestic production, boosting employment in their home countries, reducing dependence on risky sources, and rethinking lean inventories and just-in-time replenishment strategies. The pandemic has exposed vulnerabilities in production strategies and supply chains, leading to increased political and competitive pressures. Modern products often require specialized technological skills, and manufacturers often rely on suppliers and subcontractors who focus on specific areas. However, relying on a single supplier deep in their network increases disruption risks. To mitigate these risks, manufacturers should categorize suppliers as low-, medium-, or high-risk, using metrics like revenue impact, factory recovery time, and alternate sources.

A discussion about International export and outbound logistics of goods

In the export trade, goods and services are sold and shipped out of the jurisdiction of the country and customs authorities. While export to developed countries, Bangladesh gets some tariff facilities. It is nothing but helping the developing countries in export trade and industrialization, on the other hand, they regulate some products to enter their country at a lower price. Currently, Bangladesh is enjoying tariff-free market access for 90 per cent to 100 per cent products in all the developed countries except the United States. Tariff-free and low-tariff market access facilities in the developed and some developing countries immensely benefited Bangladesh. Bangladesh High Commissioner to Ottawa wrote that quality of Bangladesh’s apparel products as well as efficient supply-chain mechanism has largely contributed to doubling bilateral trade in a decade.

What SCM Professionals Overlook When it Comes to Optimizing!

Decreasing the amount of packaging a firm is using can reduce waste and increase positive public perception of your organization. Ideally, a supply chain will be conscious of the cost-cutting importance of recycled materials. Taking an audit of packaging can reveal ways to “cut the fat” and make the packaging a lean machine that helps to keep the workflow moving along nicely. Many things happen in the supply chain that is hard to control. Technology in the warehouse, in transportation for inventory, and more is incredibly important but there are other smaller, less expensive steps that some companies have been using that not only optimize the chain but also save money and improve public perception. Every supply chain executive has the duty of auditing the process to make changes where improvements are possible. This is a simple plan to integrate into the system with the right packaging option. A common mistake that we find in many supply chains is the tendency to overpack goods for shipping and storage. The goal is to use packaging that delivers flexible options i.e., easy to manage, easy to store, does not generate waste and delivers the best value. When our supply chain is using packaging that the supply chain cannot reuse, we are essentially throwing good money after bad. According to statistics, there were over 35.4 million tons of paper and cardboard generated in 2016 and (16.3 million tons for each of these waste materials in 2016 and that was just in the EU! In the United States, packaging waste is around 77 million tons just in cardboard packaging waste. Even supply professionals who are not well-versed in packaging will understand the importance of using packaging that enhances workflow, and protection and reduces risk. In the perfect packaging scenario, our packaging needs to be recycled in the supply chain. The costs of waste generated by packaging materials are tremendous not just economically but environmentally as well.

How Does Semiconductor Technology Impact the Global Supply Chain?

The industry`s annual semiconductor sales revenue has since grown to over $481 billion, as of 2018. In 2021, the sales of semiconductors reached a record $555.9 billion, up 26.2 percent with sales in China reaching $192.5 billion, according to the Semiconductor Industry Association. To make the semiconductor supply chain sustainable, companies need to focus on environmental processes, social practices, and the economy. In order to generate a sustainable future, supply chains should work to improve the manufacturing process and quality, reduce the environmental impact, and protect labor rights. Take time to learn about semiconductor supply chains so you are informed of their impact on the technological industry. As strains between China and the US worsen over Taiwan, and countries across the world reassess connections with Russia following its war In Ukraine, efforts to de-risk chip technologies are causing a realignment of supply chains according to geopolitical relations.

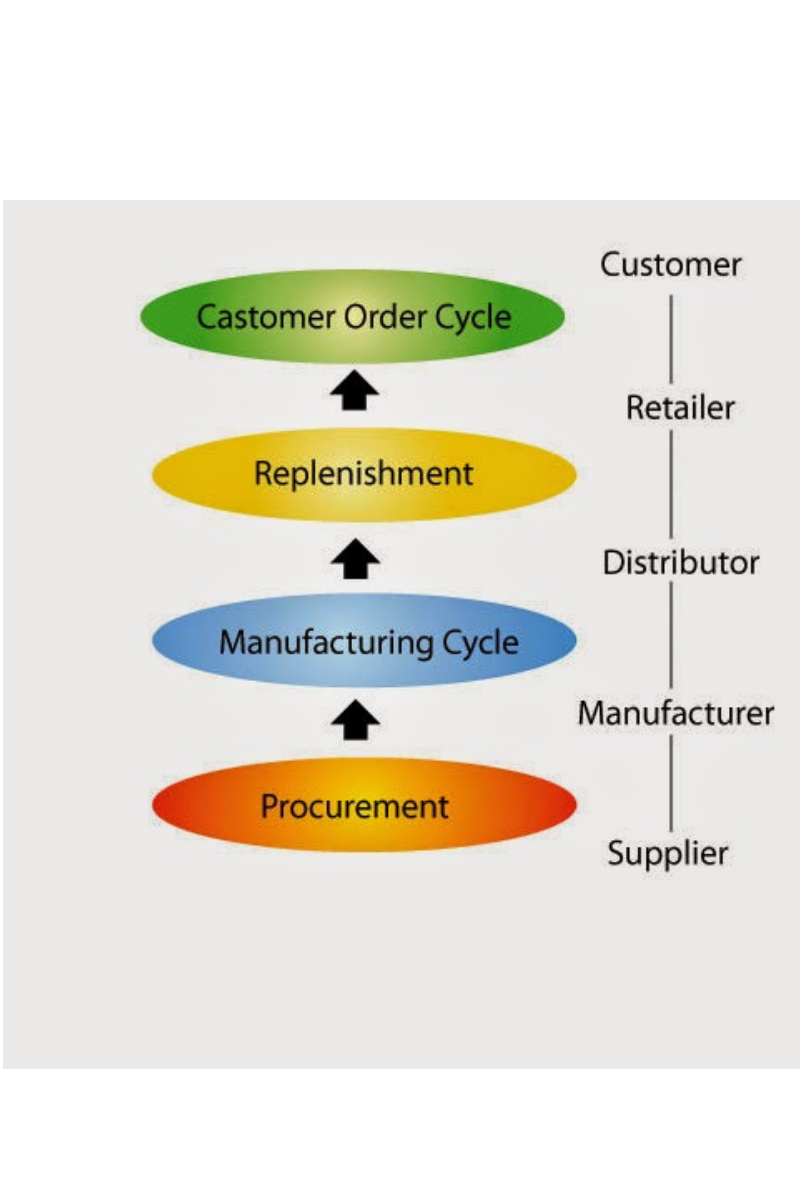

Cycle View of a Supply Chain: The Processes ।

The processes in a Supply Chain are usually divided into a series of cycles, each performed in the interface between two interrelated successive stages of a Supply Chain. Sub-processes in each Supply Chain Process Cycle I.e., each cycle comprises six sub-processes, supplier stage markets a product, buyer stage places order, supplier stage receives order, supplier stage supplies order, buyer stage receives supply, buyer returns reverse flows to a supplier or the third party.

How supply chain planning works: A general discussion

The uncertain nature of the customer demand need to take into consideration by generating the production plan and in particular the production quantities, to meet uncertain customer demand in the best way possible and maximize the profit, by minimizing production costs. Aggregate planning is a process by which a company decides about their ideal levels of capacity, production, inventory, stock-out situations, pricing, subcontracting, etc. Production planning, is the correct placement of production orders concerning place, or region, of production, and time scheduling and sequencing of production orders. The parameters are usually production rate, workforce, overtime, machine capacity level, subcontracting, backlog, and inventory on hand. The amount of overtime production planned is a parameter for aggregate production planning. Production planning for fashion apparel products has to cope with demand uncertainties. Collaborative forecasts created by various enterprises are an important input in aggregate supply chain planning. However, at the time of generating the production plan, the predicted customer demands are largely uncertain.