Package carriers, such as DHL, FedEx, UPS, etc. usually carry letters and other small cargo weighing below 150 pounds using air, Truck, and rail to carry time-sensitive smaller packages. Companies use air cargo carriers for larger cargo and package carriers for more time-sensitive smaller cargo. A carrier takes investment decisions regarding their equipment; Shipper in contrast uses transportation to minimize total cost, while providing an appropriate level of responsiveness to the customers. The Key issues air carriers usually face include identifying the location and a number of hubs, assigning planes to routes, and maintaining a schedule of planes and crews, also available at different prices. The effectiveness of any mode of transportation is affected by the carrier as well as infrastructure and transportation policies, e.g., an airline’s goal is to maximize the daily flying time of a plane and generated revenue per trip. Supply Chains using modes of transportation, such as air, package carriers, trucking, rail, water, pipelines, intermodal, etc. The cargo moves from the factory premises to the port in a truck or multi-modal movement of truck and container on the rail. The shipper requires the movement of products from one point to another in a Supply Chain and Carrier is the party who moves the cargo. AI algorithms can optimize routes for each autonomous vehicle in real-time, based on traffic data, road conditions, and other factors. AI algorithms can mine historical and real-time traffic data to create predictive models to anticipate traffic congestion and accidents. AI will manage the optimum distance between vehicles, maintain constant communication between vehicles, and plan the formation of vehicle clusters to ensure consistent traffic flow and avoid bottlenecks. Air carriers usually carry below 500 pounds, high-value, and lightweight products.

Category: Supply Chain Management

Supply Chain Management Career: A Discussion in general

In a case study, based on USA-based companies, first-level management is of about 0-4 years.To understand the supply chain management career we can remind ourselves about the example of leaf cutter ants.But Supply Chain Managers attempt and optimize the steps to produce the necessary amount of product and deliver the product to the end user at the right time when consumers need it.APICS, Founded in 1957 as American Production and Inventory Control Society and re-branded as The Association for Supply Chain Management in 2018, launched their CSCP (Certified Supply Chain Professional) programme in 2006. Institute for Supply Management, Founded in 1915 as the National Association of Purchasing Agents, launched its CPSM Certified Professional in Supply Management programme in 2008. Council of Supply Chain Management Professionals, Founded in 1963 as the Council of Logistics Management, launched their SCPro programme in 2011.For Supply Chain Management roles, “Process Engineer”, and “Supply Chain Analyst”.For Supply Chain Systems Manager roles, “ Supply Chain Manager”, Vice President, Supply Chain Management”.For Sales and Customer Service roles, “Account Specialist”/ “Customer Service”, “Customer Service Manager”, “Account Manager/Supply Chain Sales” etc.

Revenue in a supply chain: Financial Risk from the third party

Carrying out thorough third party audit not only provides the necessary regulations, but it also helps mitigate against reputational financial risk and data related damage. It is required to be careful about various governmental embargo situation: Third party suppliers, logistic service providers should prevent themselves from buying from or selling to anyone on the relevant restricted company lists maintained by various governments, such as Australia, Canada, the UK and the US. On the other hand, this is a strategy which results in higher supply chain profit than a price of the whole duration of sales season. To increase the profit margin Supply Chain Managers must use all the levers available, including price. Third type of approach he can adopt is at high demand season, he can take lower price, and low demand season, he can take a higher price.

Weather impacts on supply chain management: An analysis

Supply chains engender great opportunities for the weather forecasting industry to advance. Those who can utilize these kinds of forecasting, are beneficial to some extent and preserved from loss of weather disruptions. On one hand, the impact of weather in many cases increases the cost of the supply chain, on the other hand, it decrements the visibility of the supply chain due to inclement weather. Various weather stations measure weather data such as rainfall, shipping, etc. Weather cognate courses are being evolved for supply chain managers to tackle weather disruption issues well. The other utilization of weather reports from third-party companies can help forecast early solutions and point out the affected areas.

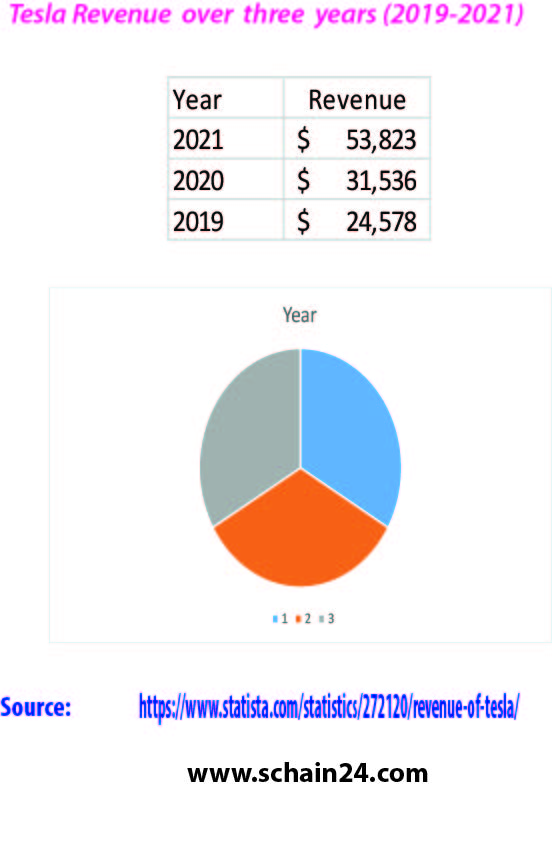

Tesla’s supply chain and logistics: A case study

The company was incorporated as Tesla Motors, Inc. on July 1, 2003, by Martin Eberhard and Marc Tarpenning. Eberhard verbalized he wanted to build a car manufacturer that is additionally a technology company, with its core technologies as the battery, the computer software, and the proprietary motor. Tesla Motors has become kenned for engendering well-designed and innovative electric conveyances. To assemble its cars, Tesla sources components from a range of Tesla suppliers. Some suppliers provide mundane car components; others provide electric conveyance components.

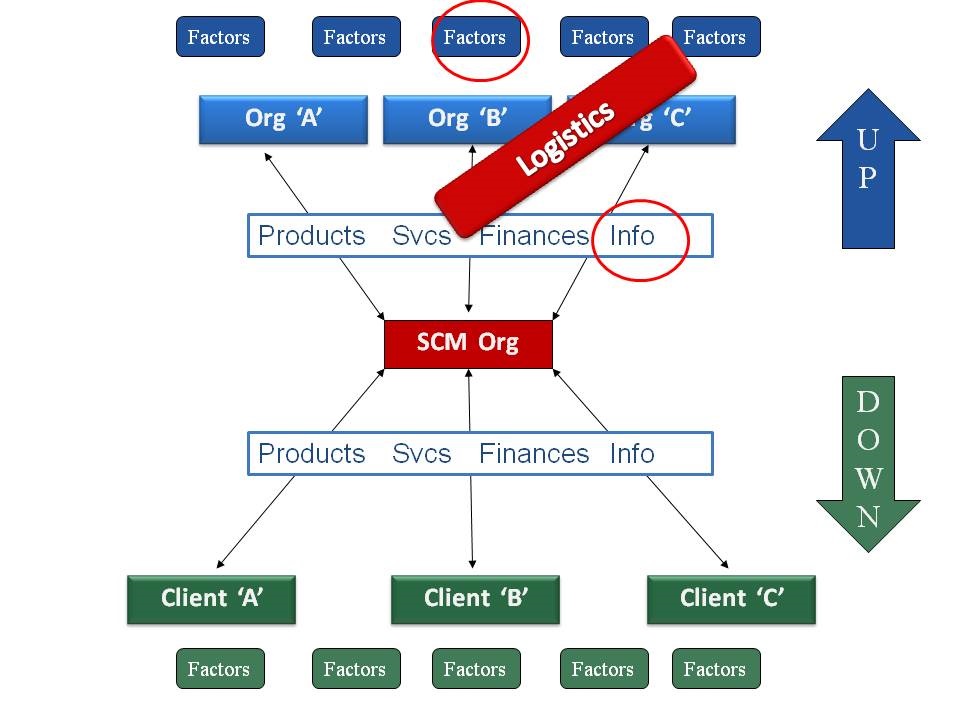

Supply Chain Management and its Drivers:

Abstract The logistical drivers are facilities, inventory, and transportation. Inventory denotes all raw materials, WIP, and finished goods in a supply chain. On the other hand, transportation involves moving inventory from point to point. Information is data about facilities, inventory, transportation, costs, prices and customers throughout the supply chain, also gives shipping options to managers. Pricing drivers determine the price […]

A brief discussion about digital supply chain management

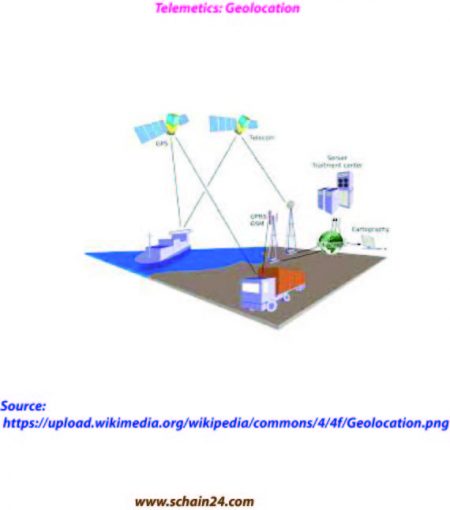

Digital supply chain risk due to the potential for Internet of Things (IoT) security vulnerabilities, which arise when assets and machines share data via sensors and software, the digital supply chain may be exposed to danger. Stages of digital supply chain management involve planning out processes and inventory before advancing to order management.