It has been found that 27.97 million vaccines are being administered every day. But only 2.3% of people in low-income countries received at least a first vaccine by September 2021, according to official reports from national health agencies, which is collated by Our World in Data. Concerns exist about whether some countries producing vaccines may impose protectionist controls by export restrictions. So that it would stockpile a COVID 19 vaccine for their own population. In June, the Serum Institute of India – a major manufacturer of global vaccines – reached a licensing agreement with AstraZeneca to make 1 billion doses of vaccine for low-and-middle-income countries, of which half of the doses would go to India. This is an issue of supply chain management to manufacture and send it to the end-user.In the United States, restrictions on vaccine eligibility have been lowered. And wealthier individuals from other countries with unhurried vaccination rates were reportedly traveling to the United States to be vaccinated.

Category: Supply Chain Management

United Parcel Services. Inc. (UPS): An SCM case study

The American Messenger Company, founded in 1907, primarily focused on package delivery to retail stores and special delivery mail for the U.S. Post Office. In 1913, it acquired a Model T Ford as its first delivery vehicle. In 1919, the company expanded to Oakland, California, changing its name to United Parcel Service. UPS became one of the only companies in the United States to offer common carrier service, expanding to areas up to 125 miles outside the city. UPS faced direct competition with USPS and the Interstate Commerce Commission, but the common carrier service was applied in cities where UPS could use the service without the authority of the ICC and state commerce commissions. In 1953, UPS resumed air service called UPS Blue Label Air. UPS expanded its operations to serve all 48 contiguous states in the United States, Canada, and West Germany. In 1991, UPS relocated its headquarters to Sandy Springs, Georgia, and acquired Haulfast and Carryfast, rebranding them UPS Supply Chain Solutions. UPS offers international package services to over 220 countries and territories worldwide. The company faces competition from major domestic carriers like the United States Postal Service (USPS) and FedEx, as well as regional carriers like OnTrac and LSO. UPS has partnered with the US Postal Service to offer UPS Mail Innovations and “SurePost,” which use the UPS Ground network to deliver packages weighing under 10 pounds to the nearest UPS Package Center. UPS has received a “striding” environmental scorecard and received the Clean Air Excellence Award from the US Environmental Protection Agency.

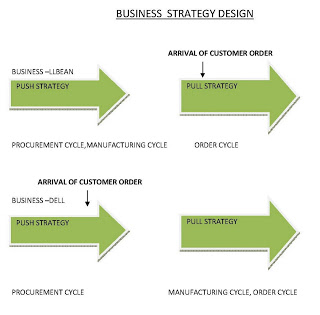

About the Push-Pull view of Supply Chain Process ।

The Supply Chain processes start cases with the express market needs, which pushes research and development, which pushes production and production pushes marketing to meet the already expressed demand. If the customer orders are speculative and order execution is initiated based on anticipation, then the Supply Chain process is under the “Push” process. Demand is not filled from finished product inventory but from production. In Logistic Chains or supply chains, the stages are operating normally in both a “Push” and “Pull” manner. The Supply Chain processes start sometimes with research and development, which pushes Production. The execution of the Supply Chain process is reactive to customer demand.

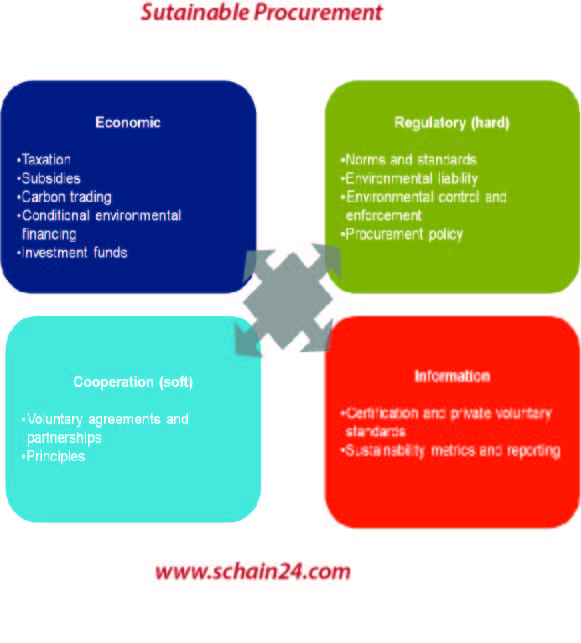

Sustainable Procurement: A Concept Used In SCM And Beyond.

There are different levels of focus in the dimensions of sustainability and also sustainable procurement. Focus on the supply chain network entails managing and balancing the supplier portfolio. The impact of fair trade or eco-labels can be on end-user buying behavior. CSR purchasing policies and CSR functions are integrated with purchasing.

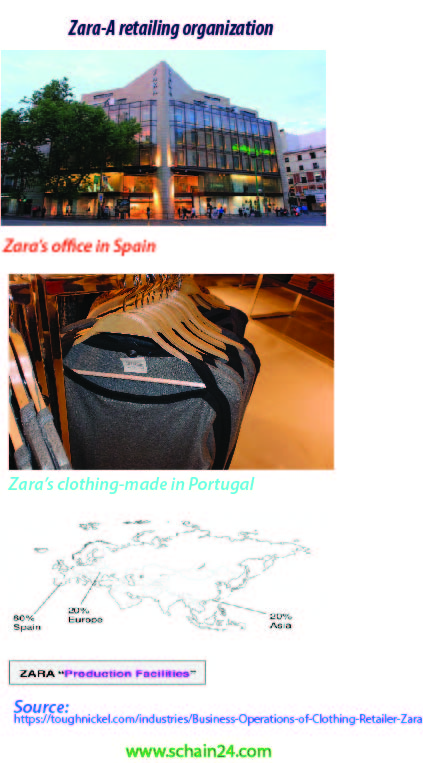

Zara, a Retailing Organization: An SCM Case Analyzed ।

The retailing organization Zara has suppliers from about 50 countries. Zara is called “Fast fashion” in a segment of the market. Following things in Zara’s ICT try to seamlessly coordinate between organizations and enhance supply chain integration. The organization’s technology improves operational responsiveness to customers, at the same time reduces cost. her main strategy is to answer quickly to consumer demand and anticipate consumer trends through IT and human resources. Zara continues to update information based on checking with store managers using PDA and updating customers’ responses.

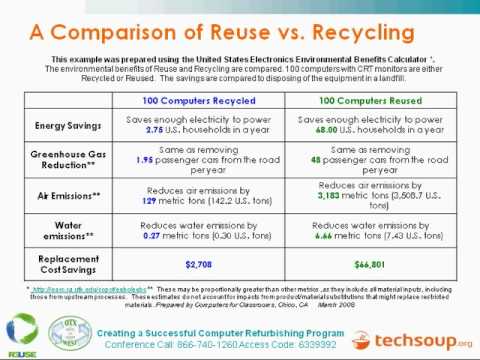

Understanding the “Reverse Logistics” concept and implications in Supply Chain Management

Returns avoidance, gate keeping, disposal and other supply chain issues are related with reverse logistics. The product may need to travel in reverse through the entire supply chain network to retain use of any service from the defective goods. There are closed loop supply chain networks that include returns processing and manufacturer has the intention to capture additional value and integrate all supply chain activities. Usually, asset based three 3PLs work as third party who are specialized in waste management and related activities. Reuse of manufactured and sold goods After sales service and returns management are sometimes related to the logistic companies.

Supply Chain Analytics: A conceptual discussion

A study supports the concept of an analytics culture built on advanced data management processes, technologies, and talent. SCAG can strengthen firms’ core features, such as ambidexterity, adaptability, and swiftness, enabling them to upgrade their performance in terms of sales, profit, and return on investment. SCAC can improve end-to-end supply chain productivity and eliminate market fragmentation. The study finds a significant positive relationship between SCAC and firm performance, with a mediating effect on supply chain agility. This could guide managers in investing in SCAC and considering complementary assets like supply chain agility to achieve a continued competitive advantage. SCAC can accelerate FPER by establishing robust agility in operations.