The U.S.-China trade war and the Covid-19 crisis have prompted manufacturers worldwide to reassess their supply chains, focusing on increasing domestic production, boosting employment in their home countries, reducing dependence on risky sources, and rethinking lean inventories and just-in-time replenishment strategies. The pandemic has exposed vulnerabilities in production strategies and supply chains, leading to increased political and competitive pressures. Modern products often require specialized technological skills, and manufacturers often rely on suppliers and subcontractors who focus on specific areas. However, relying on a single supplier deep in their network increases disruption risks. To mitigate these risks, manufacturers should categorize suppliers as low-, medium-, or high-risk, using metrics like revenue impact, factory recovery time, and alternate sources.

Tag: Management of Cross-Functional Drivers in a Supply Chain

The Sustainable Development Goals (SDGs): Its Effects On Businesses and Brands

Achieving the Sustainable Development Goals (SDGs) is a critical role for businesses and brands, as it can have a big impact on their operations, strategies, branding, and stakeholder interactions. In order to meet global sustainability goals, promote innovation in goods and services as well as business models, and draw in socially conscious clientele, companies are incorporating the Sustainable Development Goals (SDGs) into their plans. ESG factors are also being considered by investors when making decisions, and businesses that support the SDGs stand to gain access to sustainable finance sources and a greater number of investments.

Goals such as “Climate Action” and “Responsible Consumption and Production” can encourage companies to streamline their supply chains, cut waste, and use more environmentally friendly production techniques. Governments are putting SDG-aligned laws into effect, and businesses need to follow them to avoid fines or reputational harm.

Letter of Credit and Blockchain Technology In A Supply Chain |

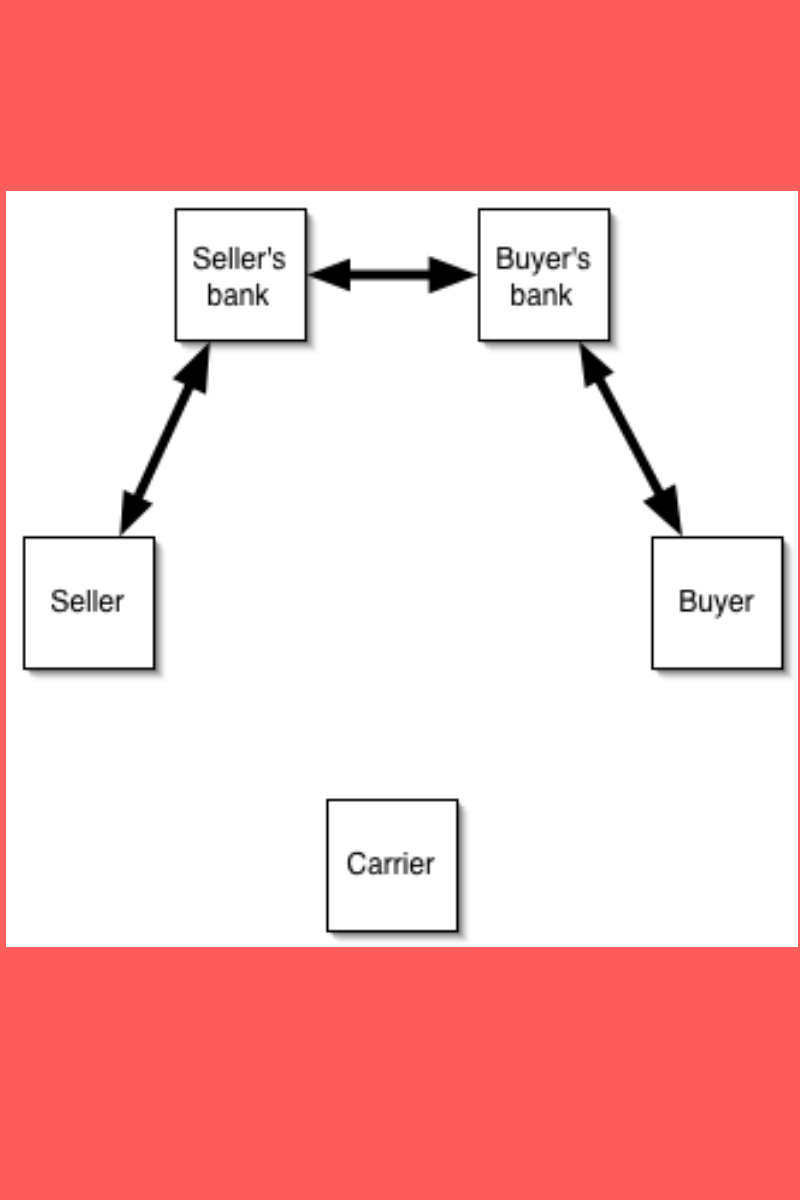

A letter of credit(LC) is also named a documentary credit(DC) in globalized international trade. In recent times, banks utilize blockchain technology regarding the formulation of letters of credit . The ICC regulates market practices (Documentary Credit 600). These include the advising bank that will give the documentary credit to the beneficiary or their nominated bank and provide their nominated bank with any amendments to the letter of credit. The bank retains a certain percentage of the letter of credit value for security. Blockchain technology is available for the letter of credit procedure and trade finance is related to it. Commerce and international trade finance include products such as issuing letters of credit, indemnifying Bills of Lading, etc. Although the letter of credit was created in the old world, methods managing the shipping of goods and related accommodations. But there is a great potential to supersede these paper processes with digitized operations utilizing blockchain technology. International trade requires a number of participants to interact with one another, i.e., the exporters, importers, banks, shipping companies, port-related entities, and customs. Trade finance in supply chain management(SCM) includes products such as lending, issuing letters of credit, factoring, export credit, and indemnification. Therefore, we can say that letter of credit and blockchain technology both are used in A Supply Chain for running international trade safely.

How to explain the rise of ecommerce challenges and opportunities for supply chain management?

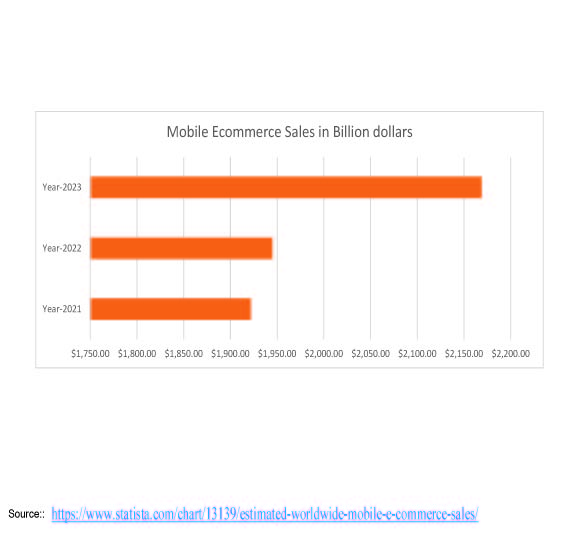

The rise of e-commerce has brought significant changes to the global economy, altering industries and consumer behavior. However, it has also presented challenges and opportunities for supply chain management. E-commerce has led to an increase in demand for quick order fulfillment, requiring more sophisticated logistics networks and faster delivery services. Inventory management has become more complex, with the need for real-time visibility and accurate demand forecasting to prevent stockouts and overstocking. Achieving transparency across the supply chain is crucial for accurate and on-time order fulfillment, while managing returns efficiently is important for customer satisfaction and cost control. Integrating supply chain management with e-commerce platforms allows companies to provide a seamless shopping experience with real-time tracking information and multiple delivery options. An agile and responsive supply chain enables companies to adapt quickly to changes in customer demand and external disruptions, ensuring high levels of customer satisfaction and loyalty. By adopting automation and digital technologies, companies can lower costs, increase efficiency, and gain a competitive edge in the fast-paced e-commerce environment. So, there are Ecommerce challenges and opportunities for supply chain management.

How Does Semiconductor Technology Impact the Global Supply Chain?

The industry`s annual semiconductor sales revenue has since grown to over $481 billion, as of 2018. In 2021, the sales of semiconductors reached a record $555.9 billion, up 26.2 percent with sales in China reaching $192.5 billion, according to the Semiconductor Industry Association. To make the semiconductor supply chain sustainable, companies need to focus on environmental processes, social practices, and the economy. In order to generate a sustainable future, supply chains should work to improve the manufacturing process and quality, reduce the environmental impact, and protect labor rights. Take time to learn about semiconductor supply chains so you are informed of their impact on the technological industry. As strains between China and the US worsen over Taiwan, and countries across the world reassess connections with Russia following its war In Ukraine, efforts to de-risk chip technologies are causing a realignment of supply chains according to geopolitical relations.

What are The Impacts of RobotMeta on Supply Chain Management: A Case Study

Abstract RobotMeta is a flexible industrial robot company that specializes in welding applications. Their robots are user-friendly, allowing small and medium-sized enterprises (SMEs) to integrate robotic solutions into their operations. They offer ready-to-weld packages including synergic or pulse (MIG/MAG) systems, which are easy to set up and use. RobotMeta’s robotic welding system reduces the time required for welding operations, enabling […]

Box Logistics, Containerization, Ports In A Global Shipping Network

Abstract Containers are the primary mode of transportation for maritime import and export flows, with 75% of total cargo carried by containers in developed areas of a global shipping network. Containerization allows for efficient distribution processes, and transshipment activities, such as warehousing, are integrated with production, distribution, and competitive supply chain strategies. Global Production Networks (GPNs) have become essential for […]