Featured Posts

View AllWhat is meant by “Last Mile Delivery” as related with future urban logistics?

- ikram

- September 4, 2025

- 0

Trending Posts

View AllWhat Is Sustainable Procurement As A Concept Used In SCM And Beyond? |

- ikram

- December 18, 2025

- 0

There are different levels of focus in the dimensions of sustainability and also in what…

What Makes Toyota’s Supply Chain Management a Benchmark for Excellence? |

- ikram

- November 27, 2025

- 0

Toyota has an effective supply chain strategy that puts value and efficiency first. It has…

A Case Study: Supply Chain Management of BYD Company Ltd. |

- ikram

- November 12, 2025

- 0

BYD, initially a battery manufacturer, has evolved into a leading player in the new energy…

The Sustainable Development Goals (SDGs): Its Effects On Businesses and Brands |

- ikram

- October 20, 2025

- 0

Achieving the Sustainable Development Goals (SDGs) is a critical role for businesses and brands, as…

Latest Posts

View AllHow Does Semiconductor Technology Impact the Global Supply Chain?

- ikram

- June 21, 2025

- 0

The industry`s annual semiconductor sales revenue has since grown to over $481 billion, as of 2018. In 2021, the sales of semiconductors reached a record $555.9 billion, up 26.2 percent…

What are The Impacts of RobotMeta on Supply Chain Management: A Case Study

- ikram

- June 5, 2025

- 0

Abstract RobotMeta is a flexible industrial robot company that specializes in welding applications. Their robots are user-friendly, allowing small and medium-sized enterprises (SMEs) to integrate robotic solutions into their operations.…

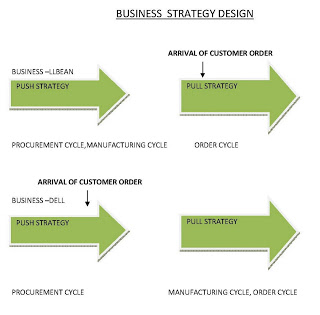

About the Push-Pull view of Supply Chain Process ।

- ikram

- May 25, 2025

- 4

The Supply Chain processes start cases with the express market needs, which pushes research and development, which pushes production and production pushes marketing to meet the already expressed demand. If…

How to Explain Toyota’s Financial Management Philosophy? : A Case Study |

- ikram

- May 2, 2025

- 0

Toyota's financial management philosophy is conservative, with a low debt-to-equity ratio and a focus on retained earnings.The company's ambition is carefully calculated and backed by a strong equity base. Toyota's…

Supply Chain Management

View AllHow to enhance supply chain management efficiency using AI technology? |

- ikram

- July 3, 2025

- 0

AI uses historical sales, market trends, weather, and social media to predict demand with higher accuracy so that it enhances…

How Does Semiconductor Technology Impact the Global Supply Chain?

- ikram

- June 21, 2025

- 0

The industry`s annual semiconductor sales revenue has since grown to over $481 billion, as of 2018. In 2021, the sales…

What Is Sustainable Procurement As A Concept Used In SCM And Beyond? |

- ikram

- December 18, 2025

- 0

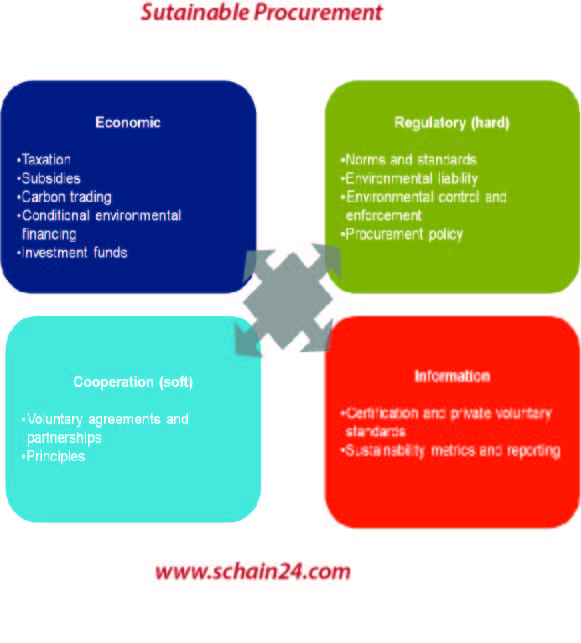

[caption id="attachment_3658" align="aligncenter" width="271"] Sustainable procurement[/caption] Abstract There are different levels of focus in the dimensions of sustainability and also in what is sustainable procurement. Focus on the supply chain…

What Makes Toyota’s Supply Chain Management a Benchmark for Excellence? |

- ikram

- November 27, 2025

- 0

Abstract Toyota has an effective supply chain strategy that puts value and efficiency first. It has adopted the Just-In-Time (JIT) system, which guarantees on-demand delivery of materials and components while…

A Case Study: Supply Chain Management of BYD Company Ltd. |

- ikram

- November 12, 2025

- 0

Abstract BYD, initially a battery manufacturer, has evolved into a leading player in the new energy vehicle (NEV) sector. The supply chain management of BYD Company Ltd is characterized by…

The Sustainable Development Goals (SDGs): Its Effects On Businesses and Brands |

- ikram

- October 20, 2025

- 0

Abstract Achieving the Sustainable Development Goals (SDGs) is a critical role for businesses and brands, as it can have a big impact on their operations, strategies, branding, and stakeholder interactions.…

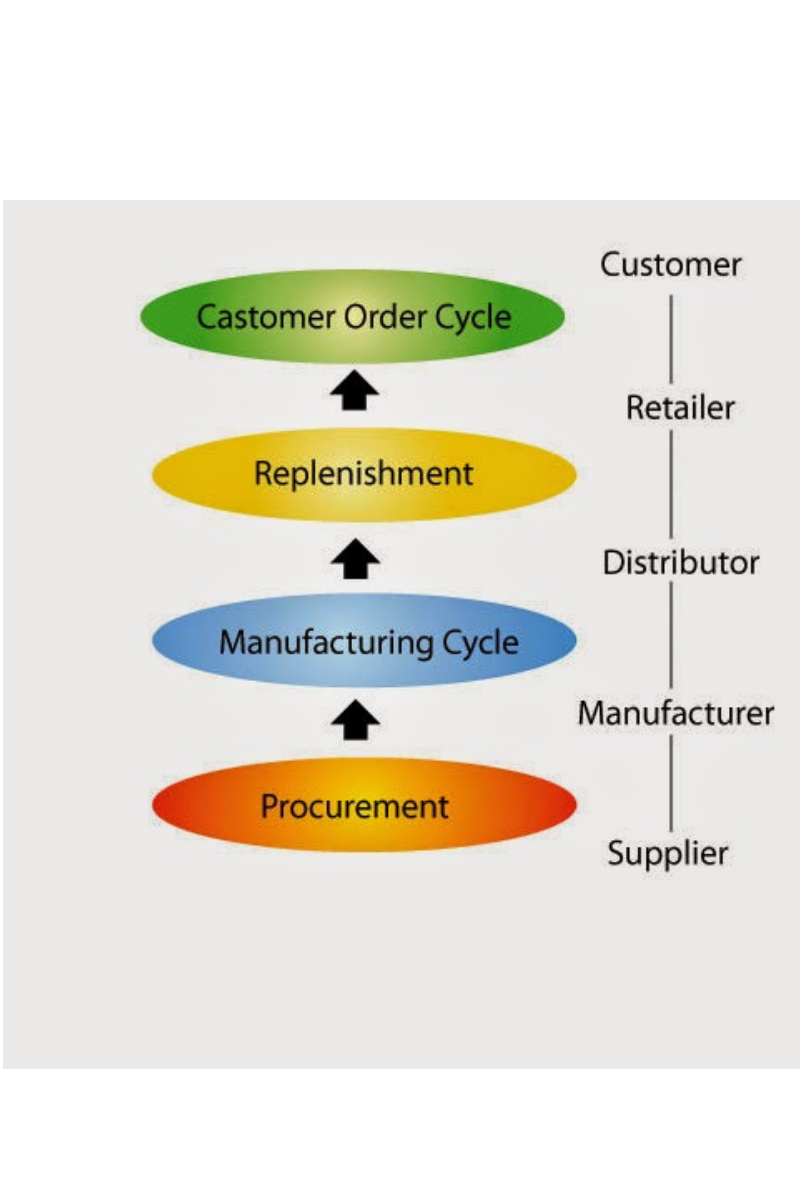

What is Cycle View of a Supply Chain? Is it Useful? |

- ikram

- December 12, 2024

- 6

The processes in a Supply Chain are usually divided into a series of cycles, each performed in the interface between two interrelated successive stages of a Supply Chain. Sub-processes in…

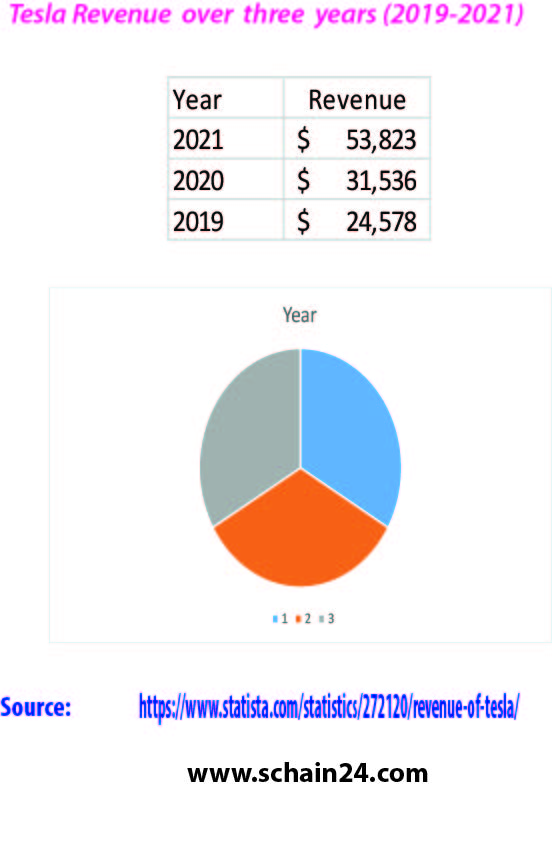

Tesla’s supply chain and logistics: A case study

- ikram

- May 1, 2023

- 0

The company was incorporated as Tesla Motors, Inc. on July 1, 2003, by Martin Eberhard and Marc Tarpenning. Eberhard verbalized he wanted to build a car manufacturer that is additionally…

H & M Supply Chain management: A case study

- ikram

- January 8, 2023

- 0

Hennes & Mauritz AB is a Swedish multinational clothing-retail company known for its fast-fashion clothing for men, women, teenagers, and children. As of November 2019, H&M operates in 74 countries…

What Makes Toyota’s Supply Chain Management a Benchmark for Excellence? |

- ikram

- November 27, 2025

- 0

Toyota has an effective supply chain strategy that puts value and efficiency first. It has adopted the Just-In-Time (JIT) system, which guarantees on-demand delivery of materials and components while cutting…

Trending

View AllWhat Is Sustainable Procurement As A Concept Used In SCM And Beyond? |

- ikram

- December 18, 2025

- 0

What Makes Toyota’s Supply Chain Management a Benchmark for Excellence? |

- ikram

- November 27, 2025

- 0

A Case Study: Supply Chain Management of BYD Company Ltd. |

- ikram

- November 12, 2025

- 0

The post Covid-19 Supply Chains: A Brief Discussion |

- ikram

- October 6, 2025

- 0

Editor’s Picks

View All

Follow Us On

Popular Posts

View AllRecent

View AllWhat Is Sustainable Procurement As A Concept Used In SCM And Beyond? |

- ikram

- December 18, 2025

- 0

There are different levels of focus in the dimensions of sustainability and also in what…

What Makes Toyota’s Supply Chain Management a Benchmark for Excellence? |

- ikram

- November 27, 2025

- 0

Toyota has an effective supply chain strategy that puts value and efficiency first. It has…

A Case Study: Supply Chain Management of BYD Company Ltd. |

- ikram

- November 12, 2025

- 0

BYD, initially a battery manufacturer, has evolved into a leading player in the new energy…

The Sustainable Development Goals (SDGs): Its Effects On Businesses and Brands |

- ikram

- October 20, 2025

- 0

Achieving the Sustainable Development Goals (SDGs) is a critical role for businesses and brands, as…