Introduction: In a supply chain management, the first decision the shipper need to take, whether they will make transportation in-house or use a third party carrier. Usually, using third party carrier is mostly found. Using a third party carrier arises the question of shipper-carrier relationship management.With globalization, shipments have been increased very much. In this perspective, companies need to give […]

Month: May 2018

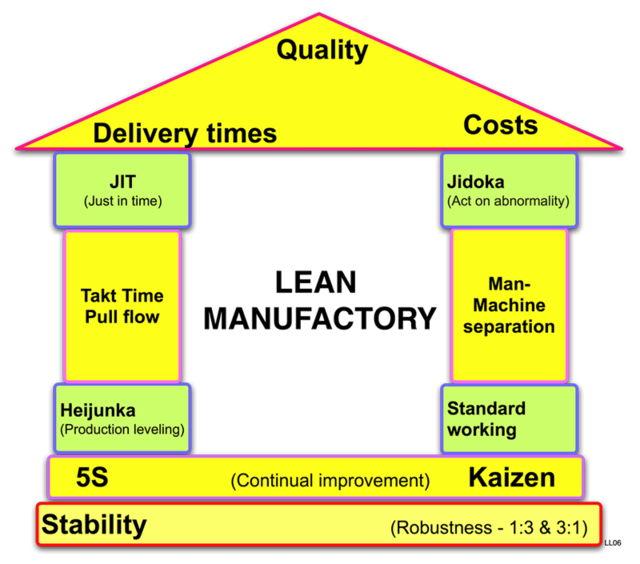

A discussion on Lean, Six Sigma and Kaizen in the context of manufacturing :

Abstract The popular definition of Lean Manufacturing and the Toyota Production System conventionally consists of the following: To solve the quandary of waste, Lean Manufacturing has The TPS is often used interchangeably with the terms Lean Manufacturing and Lean. Even more importantly, a Lean process is characterized by Lean and the Toyota Production System. The main reason of Lean Manufacturing or TPS is every step of manufacturing should be improved. Lean manufacturing involves never ending efforts to eliminate or reduce “Muda“, a Japanese term used to reduce waste, which does not add value to Supply Chain while make design, manufacturing, distribution and customer service processes in the respective Supply Chain. Things are visually displayed: For communicating with all sorts of people in the factory /supply chain unit visual displays are used as a great tool in the lean manufacturing process.Some techniques used in Lean Manufacturing to eliminate errors of the equipment operator. Keywords: TPS,Muda,Lean, 5s,Six Sigma etc. Introduction: Lean manufacturing is a synchronized method with which a supply chain can eradicate waste from its production process. According to customer needs, production process is required to develop, so that produced goods become more valuable product in quality. In contemporary manufacturing many supply […]