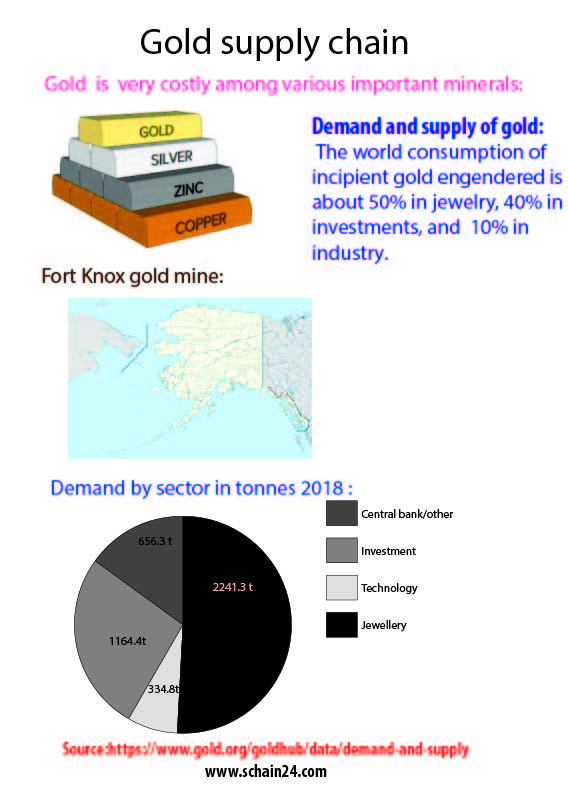

Abstract Gold is insoluble in nitric acid, which dissolves silver and base metals, a property that has long been used to refine gold and to attest the presence of gold in metallic objects, giving elevation to the term acid test.In the past, a gold standard was often implemented as a monetary policy, but gold coins ceased to be minted as […]

Author: ikram

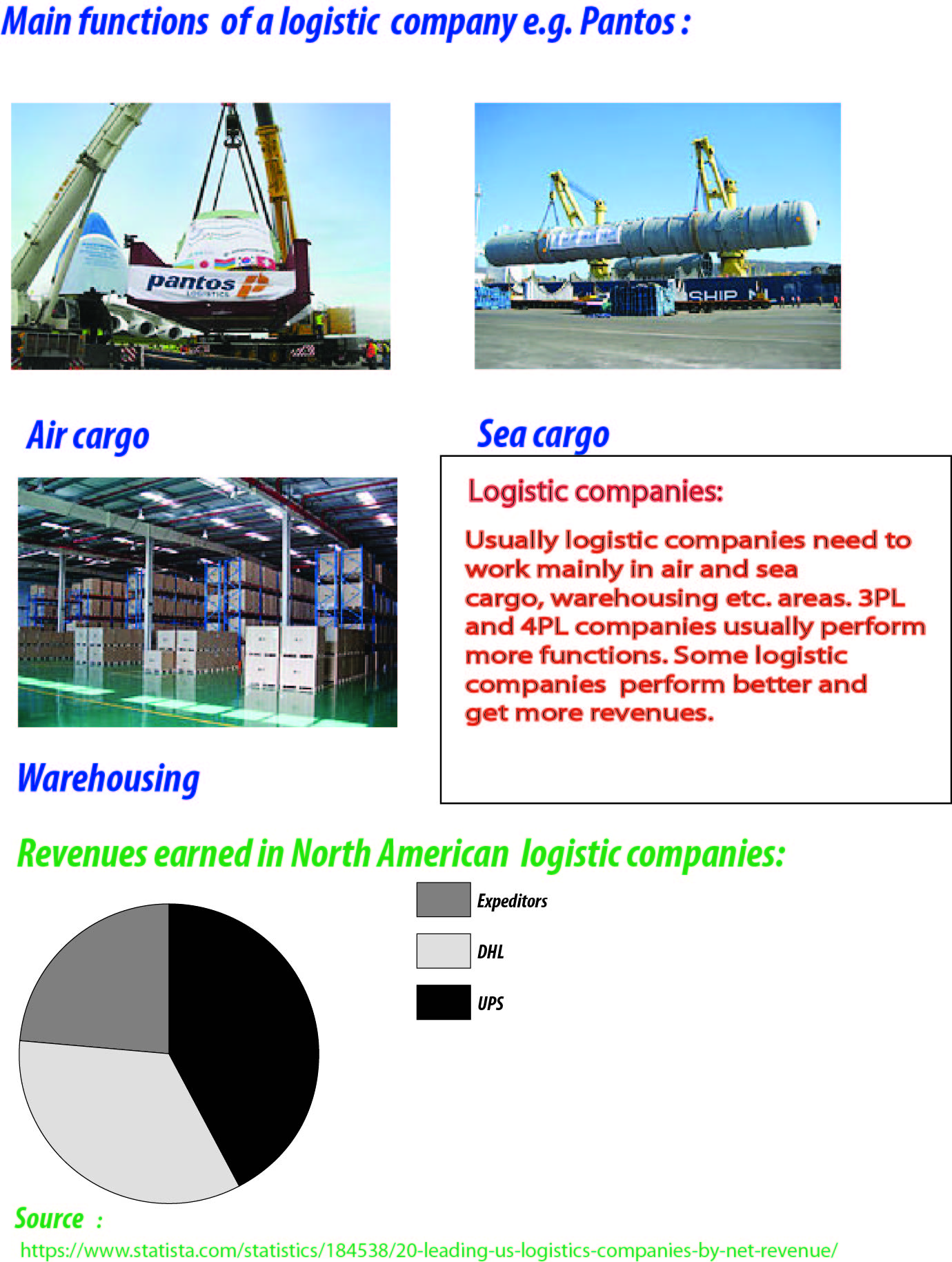

Logistics Companies and Selecting a good Logistic service provider

Abstract Procurement and logistics include market research, necessary planning, procurement decisions, logistics service provider evaluation, and order control. The main thing in advanced logistics is distribution logistics planning, which includes on-time delivery of products to the end user. Choosing a good logistics service provider is important for any company, whether it is involved in inbound logistics, outbound logistics, […]

How to Understand Supply Chain sustainability: The Walmart Example |

A sustainable supply chain is measured by triple bottom line “Impact on people, profits and the planet”, that are the upstream components of the supply chain.This shift in paradigm usually reflects the understanding that the sustainable supply chains are profitable supply chains.Now supply chain sustainability can be measured and the supply-chains can take sustainability action plans.Distribution and manufacturing optimization and rationalization, the product design and the supplier etc are involved in terms of Supply Chain.If a company is able to choose between various suppliers, to implement sustainable strategies, they can use their purchasing power to push it’s suppliers with it’s green supply chain standards.They need to audit their supplier base and make sure that inputs from suppliers are of high quality, and the use of energy, water etc.Now the world’s largest retailer Walmart has widened its sights, building networks of employees, nonprofits, government agencies, and suppliers to “Green” it’s supply chains. All these issues will help us to proceed for “How to Understand Supply Chain Sustainability.”

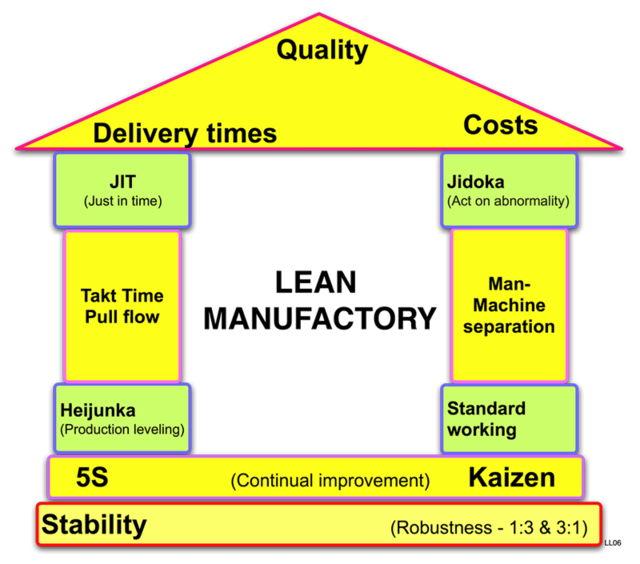

Lean manufacturing: A discussion in the perspective of apparel supply chain

Abstract: In the 1990’s a new term “Lean Manufacturing” was dubbed to replace the negative connotations of TPS. In a nutshell, Lean is a philosophical and methodological approach that strives to provide ever-increasing value to the customer through total employee involvement in the reduction of non-value-added activities and their associated costs. The main challenges which the garment industry is facing […]

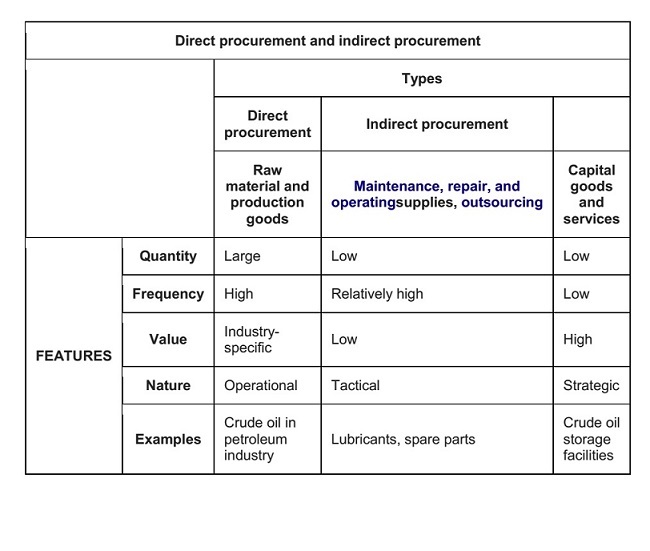

Procurement process in supply chain management: Identifying the desired focus

Abstract The materials are directly required to produce a finished product are called direct materials e.g., personal computer, hard drive etc.Direct materials are required to be available in the right place, right quantity and the right time. Direct materials are related to cost of goods, whereas an an indirect material does not determine cost directly.Indirect materials do not delay production […]

Sourcing and Procurement Decisions and Third Party Supply Chain Management Service Providers

Abstract: Supplier Scoring is used to rate Supplier performance. Impact on Supply Chain surplus and the total cost is the basis of comparison between suppliers. If the sourcing process is effective it improves profits for the firm and the total supply chain in various ways. A firm may like to keep a supply chain function in the house if outsourcing […]

Water mode of transportation in a supply chain management perspective

Abstract Due to complexity in global supply chains and networks, managing liner services has become a quite complex endeavor. A few liner services are able to fully integrate the trade routes, such as Maersk Lines and MSC. Maersk Lines has services in the Far East, Europe and North America and some hubs notably Algeciras, Salalah and Tanjung Pelapas. MSC has […]