Supply chain management (SCM) is undergoing a profound transformation driven by digitalisation, geopolitical uncertainty, sustainability pressures, and evolving market volatility. By 2026, supply chains are no longer evaluated primarily on efficiency and cost minimisation but on their ability to sense, adapt, and recover from disruption. This article examines the major emerging trends shaping supply chain management in 2026, including agentic artificial intelligence, intelligent control towers, regionalisation strategies, ESG-driven traceability, automation, cybersecurity, and workforce transformation. The analysis highlights a fundamental shift from forecast-centric planning toward decision intelligence and resilience-oriented supply chain design in the emerging trends in supply chain management.

Archives

Inside the Supply Chain Manager Position: Roles, Skills, and How to Qualify |

The Supply Chain Manager Position and the roles are crucial in connecting different parts of a business’s supply chain, ensuring the value of the supply chain increases through effective management of supplier support, transportation, and distribution practices. They manage manufacturing and distribution processes, work with procurement managers, buyers, and vendors, negotiate contracts, use software to track goods, use data analytics to forecast demand, cut costs, develop relationships with suppliers and partners, innovate supply chain processes, and stay updated on industry trends. Supply chain management is highly capital-intensive, making it increasingly important for entrepreneurs. Jobs can be in various industries, including manufacturing, government, communication, retail, education, and service sectors. The median annual salary for a senior supply chain manager is about $77,030.

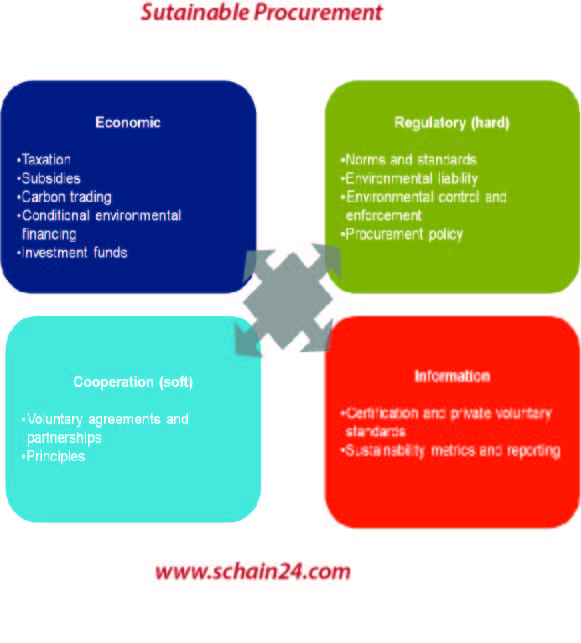

What Is Sustainable Procurement As A Concept Used In SCM And Beyond? |

There are different levels of focus in the dimensions of sustainability and also in what is sustainable procurement. Focus on the supply chain network entails managing and balancing the supplier portfolio. The impact of fair trade or eco-labels can be on end-user buying behavior. CSR purchasing policies and CSR functions are integrated with purchasing..

What Makes Toyota’s Supply Chain Management a Benchmark for Excellence? |

Toyota has an effective supply chain strategy that puts value and efficiency first. It has adopted the Just-In-Time (JIT) system, which guarantees on-demand delivery of materials and components while cutting waste and inventory expenses. By employing a tiered supplier system and incorporating employees at all levels in cooperative improvement initiatives, Toyota also cultivates long-term relationships with its suppliers. The Toyota Production System (TPS) maximizes efficiency while reducing waste and overproduction. To match production schedules with market demand, the organization employs sophisticated demand forecasting systems. Toyota also uses buffer stockpiles for essential components and dual-sourcing tactics to proactively manage supply chain risks. For improved supply chain monitoring and predictive analytics, the business incorporates cutting-edge digital technologies like IoT and AI.

A Case Study: Supply Chain Management of BYD Company Ltd. |

BYD, initially a battery manufacturer, has evolved into a leading player in the new energy vehicle (NEV) sector. The supply chain management of BYD Company Ltd is characterized by rapid battery and motor innovation and a strong backward integration model, achieving over 50% self-sufficiency in parts. This strategy has significantly reduced production costs from approximately 257,500 in 2021 to 159,000 in 2023. BYD utilizes smart supply chain practices, including AI and big data, to enhance logistics and demand forecasting. Sustainability efforts are integrated through green procurement and circular development strategies. As BYD expands internationally, it faces challenges in cross-border logistics and regulatory frameworks. Despite its strengths in cost control and supply security, issues such as slow delivery times and fragmented data systems remain. Additionally, the company must navigate ethical and regulatory risks associated with global sourcing, contrasting with Tesla’s software-driven competitiveness and distributed manufacturing strategy.

The Sustainable Development Goals (SDGs): Its Effects On Businesses and Brands |

Achieving the Sustainable Development Goals (SDGs) is a critical role for businesses and brands, as it can have a big impact on their operations, strategies, branding, and stakeholder interactions. In order to meet global sustainability goals, promote innovation in goods and services as well as business models, and draw in socially conscious clientele, companies are incorporating the Sustainable Development Goals (SDGs) into their plans. ESG factors are also being considered by investors when making decisions, and businesses that support the SDGs stand to gain access to sustainable finance sources and a greater number of investments.

Goals such as “Climate Action” and “Responsible Consumption and Production” can encourage companies to streamline their supply chains, cut waste, and use more environmentally friendly production techniques. Governments are putting SDG-aligned laws into effect, and businesses need to follow them to avoid fines or reputational harm.

The post Covid-19 Supply Chains: A Brief Discussion |

The U.S.-China trade war and the Covid-19 crisis have prompted manufacturers worldwide to reassess their supply chains, focusing on increasing domestic production, boosting employment in their home countries, reducing dependence on risky sources, and rethinking lean inventories and just-in-time replenishment strategies. The pandemic has exposed vulnerabilities in production strategies and supply chains, leading to increased political and competitive pressures. Modern products often require specialized technological skills, and manufacturers often rely on suppliers and subcontractors who focus on specific areas. However, relying on a single supplier deep in their network increases disruption risks. To mitigate these risks, manufacturers should categorize suppliers as low-, medium-, or high-risk, using metrics like revenue impact, factory recovery time, and alternate sources.