Abstract Amazon’s digital supply chain is a technological marvel, integrating software and hardware to connect every link of the chain, from suppliers to customers. It uses advanced algorithms and machine learning to predict stock needs with precision, ensuring products are available when customers want them. Amazon’s fulfillment centers feature robots and human workers, enhancing efficiency and reducing mistakes. Amazon […]

Tag: Management of Cross-Functional Drivers in a Supply Chain

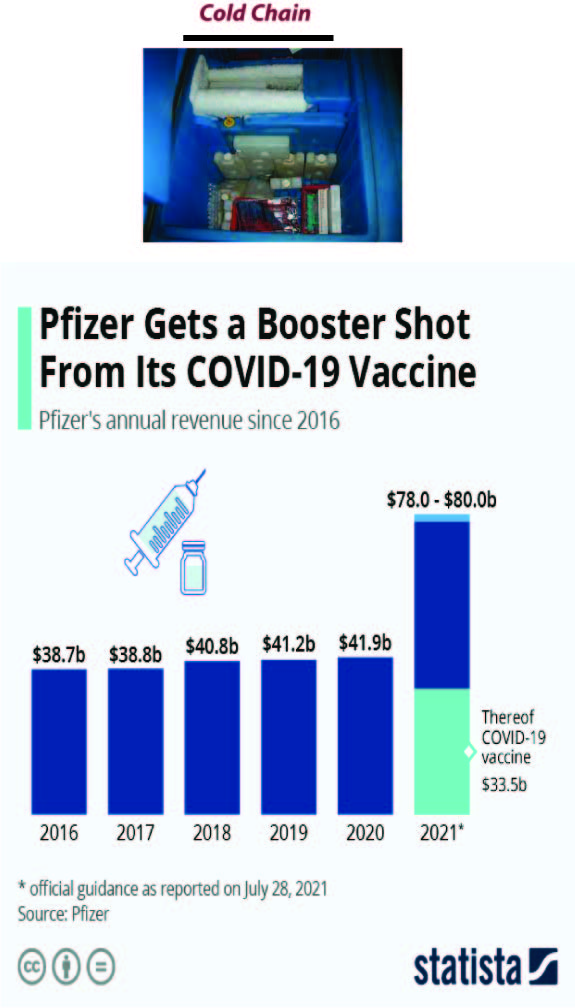

How to Explain Cold Chain as a Supply Chain and Logistical issue? |

Existing amenities are not enough to store, and deliver a large volume of vaccines within a short time, say experts. The governments are considering banking on the existing cold chain as a supply chain and logistical issue for storing, transporting, and distributing coronavirus vaccines while some professionals say the main challenge will be to manage such a large volume with the existing capacity. On November 5, 2020, the Bangladesh government signed a trilateral memorandum of understanding (MoU) with the Serum Institute of India and Bangladesh’s Beximco Pharmaceuticals Ltd to get three crore doses of Covid-19 vaccines from Serum, keeping in mind the existing cold chain. In 2020 during the COVID-19 pandemic, vaccines being developed may need ultra-cold storage and transportation temperatures as cold as −70 °C (−94 °F), requiring what has been referred to as a “colder chain” infrastructure. Disruption of a cold chain due to war may produce consequences similar to the smallpox outbreaks in the Philippines during the Spanish–American War. The distributed vaccines were inert due to a lack of temperature control in transport. There are no uniform global practices to follow, customs, legal, and compliance issues, effects on the environment, supplier-related risks, issues with cold chain delivery — packaging, hardware issues, vehicle breakdown, etc. Besides the usual elements of risk that plague normal supply chains, cutting-edge cold chain logistics has its own exclusive set of problems such as product sensitivity, the increasing cost of freight, and growing regulatory hurdles.

How Does the International ship and Port Facility Security Code Enhance Supply Chain Security?

Each ship must develop a unique plan to protect against security threats. The plan must be approved by the ship’s flag state. Port facilities must also develop a security plan to protect port infrastructure. The plan outlines the responsibilities of port facility personnel and how to respond to potential security breaches. The ISPS Code introduces a three-tiered system of security levels: Level 1: Normal security measures, Level 2: Additional security measures due to an elevated threat level, and Level 3: The highest level of security measures is activated in response to a specific threat or a known risk. Each ship and port facility must appoint a Ship Security Officer (SSO) to maintain the security plan and coordinate actions with relevant authorities. Regular training and drills are mandated for both ship and port personnel to ensure personnel are well-prepared for potential security incidents. The code sets guidelines for information sharing and cooperation between all parties to enhance maritime security. The ISPS Code has significantly improved supply chain security, particularly in the global maritime industry. It reduces the risk of terrorist attacks and piracy, enhancing the security of ports that transport goods across international borders. It encourages risk mitigation and threat assessment, enhancing the security of cargo and fostering international cooperation. It improves monitoring and surveillance, requiring port facilities to implement surveillance systems and ships to be equipped with tracking systems. It requires both ships and port facilities to have contingency plans in place in the event of a security breach or a threat. It provides guidelines for the protection of critical infrastructure against physical attacks or other types of sabotage. The ISPS Code instills confidence in global trade and by ensuring consistent security maintenance using International ship and Port Facility Security Code.

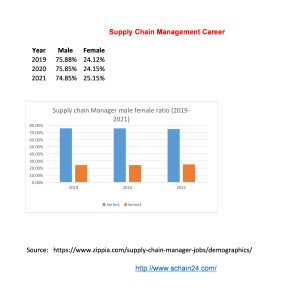

What is a Supply Chain Management Job and Career?

In a case study, based on US-based companies, first-level management is of about 0-4 years. To understand the supply chain management job and career we can remind ourselves about the example of leaf cutter ants. APICS, founded in 1957 as American Production and Inventory Control Society and re-branded as The Association for Supply Chain Management in 2018, launched their CSCP (Certified Supply Chain Professional) programme in 2006. Institute for Supply Management, founded in 1915 as the National Association of Purchasing Agents, launched its CPSM Certified Professional in Supply Management programme in 2008. Council of Supply Chain Management Professionals, founded in 1963 as the Council of Logistics Management, launched their SCPro programme in 2011.For Supply Chain Management roles, “Process Engineer”, and “Supply Chain Analyst”. For Supply Chain Systems Manager roles, “Supply Chain Manager”, Vice President, Supply Chain Management”. For Sales and Customer Service roles, “Account Specialist”/ “Customer Service”, “Customer Service Manager”, “Account Manager/Supply Chain Sales” etc.

A discussion about Unilever’s Supply Chain Management : A Case Study |

Unilever’s vast operations require a robust SCM to manage the flow of materials across continents and the company is committed to sustainable sourcing practices. Unilever’s supply chain management includes advanced technologies and lean manufacturing principles to optimize production and minimize waste. The company also uses a sophisticated logistics network for timely delivery of products and is embracing digital technologies to enhance supply chain visibility and efficiency, including the use of IoT sensors, AI-powered analytics, and blockchain. Unilever is a pioneer in sustainable practices, such as palm oil sourcing and achieving zero waste to landfill status in many factories, showing its commitment to environmental sustainability. Suppliers who meet Unilever’s criteria for climate leadership can sign the Unilever Climate Promise to demonstrate their commitment to sustainability.

United Parcel Services Inc. : UPS Supply Chain Case Study

The American Messenger Company, founded in 1907, primarily focused on package delivery to retail stores and special delivery mail for the U.S. Post Office. In 1913, it acquired a Model T Ford as its first delivery vehicle. In 1919, the company expanded to Oakland, California, changing its name to United Parcel Service. UPS became one of the only companies in the United States to offer common carrier service, expanding to areas up to 125 miles outside the city. UPS faced direct competition with USPS and the Interstate Commerce Commission, but the common carrier service was applied in cities where UPS could use the service without the authority of the ICC and state commerce commissions. In 1953, UPS resumed air service called UPS Blue Label Air. UPS expanded its operations to serve all 48 contiguous states in the United States, Canada, and West Germany. In 1991, UPS relocated its headquarters to Sandy Springs, Georgia, and acquired Haulfast and Carryfast, rebranding them UPS Supply Chain Solutions. UPS offers international package services to over 220 countries and territories worldwide. The company faces competition from major domestic carriers like the United States Postal Service (USPS) and FedEx, as well as regional carriers like OnTrac and LSO. UPS has partnered with the US Postal Service to offer UPS Mail Innovations and “SurePost,” which use the UPS Ground network to deliver packages weighing under 10 pounds to the nearest UPS Package Center. UPS has received a “striding” environmental scorecard and received the Clean Air Excellence Award from the US Environmental Protection Agency.

The Red Sea: A discussion in a supply chain perspective

The Red Sea, a major sea route connecting Europe, the Persian Gulf, and East Asia, is facing increased attacks by Houthi insurgents in Yemen since mid-November 2023. The US has announced a maritime coalition to defend shipping in the area. The Eastern shore includes Saudi Arabia and Yemen, while the Western shore includes Egypt, Sudan, Eritrea, and Djibouti. Maersk has halted all transits through the Red Sea/Gulf of Aden until further notice, while Hapag-Lloyd has extended its rerouting around Africa. CMA CGM has announced rate increases from Asia to North Europe, and carriers are redirecting Asia to US East Coast services via Panama.