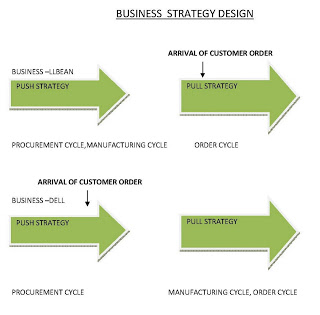

The Supply Chain processes start cases with the express market needs, which pushes research and development, which pushes production and production pushes marketing to meet the already expressed demand. If the customer orders are speculative and order execution is initiated based on anticipation, then the Supply Chain process is under the “Push” process. Demand is not filled from finished product inventory but from production. In Logistic Chains or supply chains, the stages are operating normally in both a “Push” and “Pull” manner. The Supply Chain processes start sometimes with research and development, which pushes Production. The execution of the Supply Chain process is reactive to customer demand.

Tag: Understanding Supply Chain Management Basics

How Reverse Logistics impacts on Supply Chain Management |

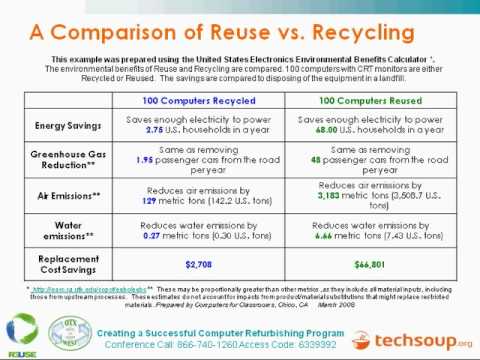

Returns avoidance, gate keeping, disposal and other supply chain issues are related with reverse logistics. The product may need to travel in reverse through the entire supply chain network to retain use of any service from the defective goods. There are closed loop supply chain networks that include returns processing and manufacturer has the intention to capture additional value and integrate all supply chain activities. Usually, asset based three 3PLs work as third party who are specialized in waste management and related activities. Reuse of manufactured and sold goods After sales service and returns management are sometimes related to the logistic companies.

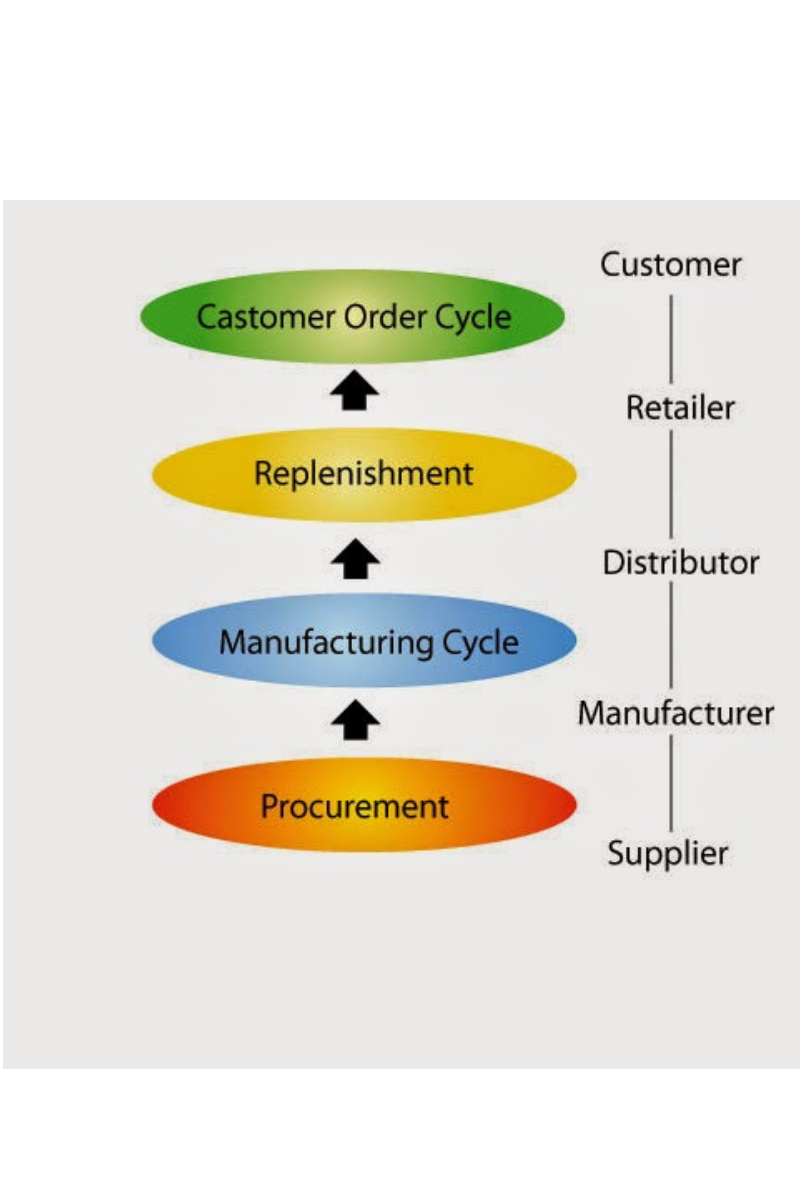

Cycle View of a Supply Chain: The Processes ।

The processes in a Supply Chain are usually divided into a series of cycles, each performed in the interface between two interrelated successive stages of a Supply Chain. Sub-processes in each Supply Chain Process Cycle I.e., each cycle comprises six sub-processes, supplier stage markets a product, buyer stage places order, supplier stage receives order, supplier stage supplies order, buyer stage receives supply, buyer returns reverse flows to a supplier or the third party.

How supply chain planning works: A general discussion

The uncertain nature of the customer demand need to take into consideration by generating the production plan and in particular the production quantities, to meet uncertain customer demand in the best way possible and maximize the profit, by minimizing production costs. Aggregate planning is a process by which a company decides about their ideal levels of capacity, production, inventory, stock-out situations, pricing, subcontracting, etc. Production planning, is the correct placement of production orders concerning place, or region, of production, and time scheduling and sequencing of production orders. The parameters are usually production rate, workforce, overtime, machine capacity level, subcontracting, backlog, and inventory on hand. The amount of overtime production planned is a parameter for aggregate production planning. Production planning for fashion apparel products has to cope with demand uncertainties. Collaborative forecasts created by various enterprises are an important input in aggregate supply chain planning. However, at the time of generating the production plan, the predicted customer demands are largely uncertain.

Revenue in a supply chain: Financial Risk from the third party

Carrying out thorough third party audit not only provides the necessary regulations, but it also helps mitigate against reputational financial risk and data related damage. It is required to be careful about various governmental embargo situation: Third party suppliers, logistic service providers should prevent themselves from buying from or selling to anyone on the relevant restricted company lists maintained by various governments, such as Australia, Canada, the UK and the US. On the other hand, this is a strategy which results in higher supply chain profit than a price of the whole duration of sales season. To increase the profit margin Supply Chain Managers must use all the levers available, including price. Third type of approach he can adopt is at high demand season, he can take lower price, and low demand season, he can take a higher price.

Supply Chain Management and its Drivers:

Abstract The logistical drivers are facilities, inventory, and transportation. Inventory denotes all raw materials, WIP, and finished goods in a supply chain. On the other hand, transportation involves moving inventory from point to point. Information is data about facilities, inventory, transportation, costs, prices and customers throughout the supply chain, also gives shipping options to managers. Pricing drivers determine the price […]