Abstract

Utilizing AI to avail people and automate processes avails the top and bottom line because companies waste an abundance of time and money on having humans perform rudimental supply chain tasks. The SAP starts the internal supply process when the purchase order is processed on the seller and an Advanced Ship Notification (ASN) is sent. Utilizing predictive analytics for supplier relationship management with data engendered from supplier assessments, audits, and credit scoring could provide a substructure for decisions regarding supplier selection and risk management. There is no doubt that the potential of AI and machine learning will determinately be achieved in the supply chain, enabling companies to eliminate waste, in many cases afore it even occurs. Delivery will include seller information, items, expected quantity and delivery details. The Delivery Monitor is used to display and open and complete the delivery process. Sizably big data insights, along with AI, can ameliorate supply chain transparency and optimization, and can potentially revolutionize the efficiency of supply chain decision-making.

Keywords: Global inbound logistics; Supply chain flexibility; Logistics flexibility.

Article:

Introduction

Inbound denotes coming inward and logistics denotes moving something from one point to another in a supply chain. The term logistics includes a wide variety of tasks, such as managing how raw materials or inputs are acquired and conveyed to the business, how inventory and inputs are stored at the business’ facilities, and how inventory is conveyed within the business and beyond. Inbound logistics customarily refers to the logistical operations of companies that operate fairly upstream. Inbound logistics refers to the internal logistics tasks and activities that businesses need to consummate in order to operate. In terms of the supply chain, it involves the relationship with parties that operate further upstream than the given business.

Characteristics of inbound logistics:

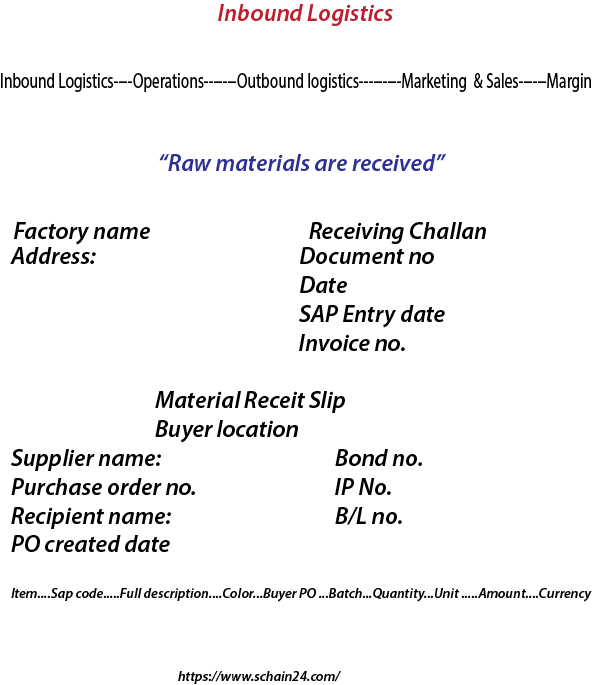

It includes material specifications, purchase amount, date and delivery schedule wanted, where the product or service purchased must be delivered, and the date that the supplier choice will be completed. The request includes an identification of requested object, quantity, date or requested delivery schedule, how the purchase must be charged, where the product or service must be delivered and the confirmation of the responsible for the approval of the purchase. Quotation requests generally ask each supplier as followed: unit price and total price, information on whether the supplier will pay the freight cost, discounts for immediate payment, and other terms of payment, date or delivery schedule, and any special conditions of the supplier. Purchase order forms include the purchase order number, shipping and billing, unit price and total price, discounts for payment in cash and any special terms of purchase. In purchasing the commodity buyer is responsible for issuing the purchase order, which will be sent to the supplier, according to the annual planning of the final customer. Inbound logistics is the way materials and other goods are brought into a company. This process includes the steps to order, receive, store, transport and manage incoming supplies. Inbound logistics focuses on the supply part of the supply-demand equation.

Using technology to improve inbound logistics

Utilizing AI to avail people and automate processes avails the top and bottom line because companies waste an abundance of time and money on having humans perform rudimental supply chain tasks. Utilizing predictive analytics for supplier cull and supplier relationship management with data engendered from supplier assessments, audits, and credit scoring could provide a substructure for decisions regarding supplier selection and risk management. Companies can significantly ameliorate network, capacity, and authorize-orchestrating decisions with AI predictive capabilities utilizing sizably big data and ERP software(s). There is no doubt that the potential of AI and machine learning will determinately be achieved in the supply chain, enabling companies to eliminate waste, in many cases afore it even occurs.

Procurement related activities

Streamlining procurement-cognate tasks can transpire through the automation and augmentation of chatbot capabilities, which require access to robust and astute data sets. On a more tactical and operational level, companies are utilizing AI in robotics and automated conveyances to track, locate, and move inventory within warehouses. Sizably big data insights, along with AI, can ameliorate supply chain transparency and optimization, and can potentially revolutionize the efficiency of supply chain decision-making. AI can avail automate processes by functioning without the desideratum for any human intervention—for example, robots performing process steps in a fulfillment center. This can sanction for automating actions such as placing purchasing requests, researching and answering internal questions regarding procurement functionalities, or receiving, filing, and documenting invoices and payment/order requests. It can additionally truncate errors, for example, utilizing a virtual assistant and in data analysis.

The SAP and the Incoming Supply

The overall visibility of their internal supply function is important for companies. Delivery management can see which inbound deliveries are coming in. It can set the right time to deliver the right resources at the right time so that the goods are returned on time without interruption from the dock. The SAP starts the internal supply process when the purchase order is processed on the seller and an Advanced Ship Notification (ASN) is sent. When an SN is available it can create an inbound DVD in SAP. Delivery will include seller information, items, expected quantity and delivery details. The Delivery Monitor is used to display and open and complete the delivery process. This is a list that is easily reviewed. It shows exhibits payable for delivery or making transfer orders for mobile phones, for which paid quantities or play stacks need to be confirmed and supplies payable for delivery of receipts of products. Product receipts are used to record items received from a seller that were sent using information from the purchase order. Product receipt is important as it allows items to be performed in stock, update stock levels and used in the item manufacturing process. If an item is found in stock, the item price is posted to the company’s account. If no inbound delivery exists, internal delivery within the system may be the beginning of the product receipt process from a good receipt document delivered or manually created.

Inbound logistics and supply chain planning

If we take an automotive industry as an example, planning of inbound logistics flexibility in global production networks is necessary. Process sequences of the overseas supply like transportation, storing or handling has different parameters regarding their respective flexibility range as well as the time- and cost-related implications of their adjustment. The approach need to support decision-making processes in international supply chain planning.

Conclusion:

Inbound logistics is related with supply chain planning. It can be easily completed if used some help of technology. A good deal of knowledge about customs and business security is also required.

Reference:

1.Sarah.Sarah, Benz. , Franziska (2018). “Flexibility planning in global inbound logistics”. At www.sciencedirect.com

2.Myerson. Paul A. (2020). “Supply Chain AI: This Time It’s for Real”.https://www.inboundlogistics.com/cms/article/supply-chain-AI-this-time-its-for-real/

3. Takita,Antonio Mitsumasa Vieira.Leite,Jandecy Cabral.(2016). “Inbound Logistics: A Case Study“. Business Management Dynamics.Vol.5, No.12, Jun 2016, pp.14-21.