Abstract:

The Supply Chain processes start cases with the express market needs, which pushes research and development, which pushes production and production pushes marketing to meet the already expressed demand. If the customer orders are speculative and order execution is initiated based on anticipation, then the Supply Chain process is under the “Push” process. Demand is not filled from finished product inventory but from production. In Logistic Chains or supply chains, the stages are operating normally in both a “Push” and “Pull” manner. The Supply Chain processes start sometimes with research and development, which pushes Production. The execution of the Supply Chain process is reactive to customer demand.

Keywords: supply chain, Push, pull, logistics.

Introduction:

The business terms “Push” and “Pull” originated in Logistic and Supply Chain Management. Relative to customer demand, supply chain processes are executed, which fall into two broad categories-“Push” and “Pull”.

The Push-Pull view of the Supply Chain process:

The execution of the Supply Chain process is reactive to customer demand. Then, it is under the “Pull” process. If the customer orders are speculative and we start order execution based on anticipation, then the Supply Chain process is under the “Push” process.

|

| Business Strategy |

Push-Pull view Business Strategy:

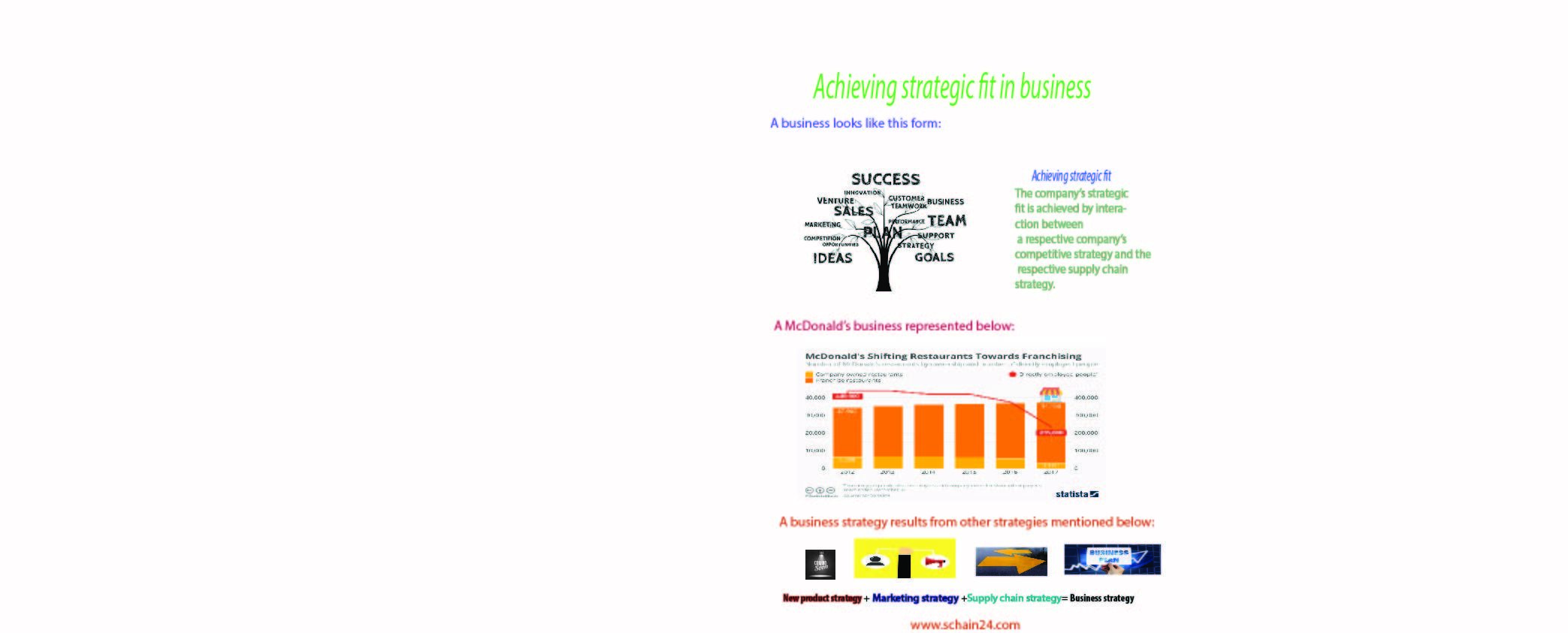

The Supply Chain processes start sometimes with research and development, which pushes Production. And Production itself pushes Marketing to create demand. The Supply Chain processes start in other cases with the express market needs, which pushes research and development, which pushes production and production pushes marketing to meet the already expressed demand.

| Push Strategy | Pull Strategy |

|

A. Used the above strategy where demand uncertainty is comparatively little. |

A. Used to that portion of the Supply Chain where demand uncertainty is high. |

|

B. Long-term forecasts drive production and distribution. |

B.Demand drives production and distribution. |

|

C. Order quantity decided based on past order patterns from the retailer warehouse. |

C. Response to the specific order. |

|

D. Unable to meet changed demand. |

D. Point of Sale data used to know the demand. |

|

E. Large inventory required. |

E. No inventory. |

|

F.Less advertising cost. |

F. Advertising costs may be higher. |

|

G. Different types of production batches easy to implement. |

G. Difficult to implement large production batches. |

The LL Bean instance:

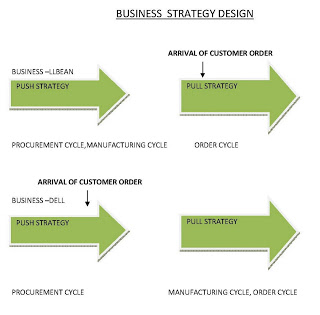

LL Bean executes all processes in the customer order cycle after the customer arrives. It performs all processes in the replenishment cycle in anticipation of demand. For Dell, which is a build-to-order computer manufacturer, the situation is different. They do not fill demand from finished product inventory but from production.

LL Bean vs. Dell strategy:

LL Bean executes all processes in the customer order cycle after the customer arrives. They perform all processes in the replenishment cycle in anticipation of demand. For Dell, which is a build-to-order computer manufacturer, the situation is different. They do not fill demand from finished product inventory but from production. In Logistic Chains or supply chains, the stages are operating normally in both a “Push” and a “Pull” manner. Between these points, there is a boundary point. To take strategic decisions which are related to Supply Chain Design the Push-Pull view is essential. This helps to identify the Push/ Pull boundary so that Supply Chain can match supply and demand effectively. Push-Pull strategy differentiated below for a better understanding of these concepts:

Conclusion:

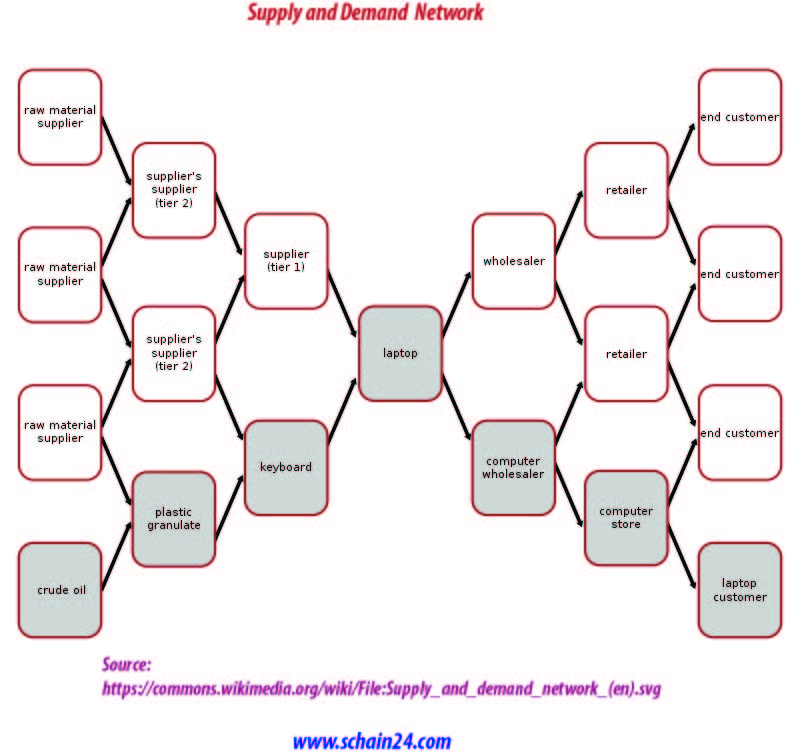

The Push-Pull strategy is applied in many Supply Chains. The Textile and Apparel Supply Chain in the current world is considered a Push-Pull Supply Chain, which is also called a synchronized Supply Chain. In this strategy, it bases the initial stages of the Supply Chain on the “Push” strategy, while the final stages are operated on a “Pull” system. The interface between push-based stages is referred to Push-Pull boundary. In the South Asian textile industry, it has been observed that being a fabric manufacturer they outsource yarn based on a forecast, and weaves as per real customer demand. The “Push” part of their Supply Chain prior to weaving, while the “Pull” part starts with weaving, which pushes part starts with weaving. Weaving is based on actual buyer demand. Uncertainty in finished demand is greater than component demand, which leads to safety stock reduction. We find that the management of the apparel supply chain moves from “Push” to “Pull” and the end to a synchronized system. Another way of explaining a supply chain is the “cycle view of the supply chain“.

Reading further:

-

Terry P. Harrison, Hau L. Lee and John J. Neale (2003). The Practice of Supply Chain Management. Springer. ISBN 978-0-387-24099-2.

-

Hopp, Wallace J.; Spearman, Mark L. (2004). “To pull or not to pull: what is the question?”. Manufacturing & Service Operations Management. 6 (2): 133–148. doi:10.1287/msom.1030.0028.

- https://youtu.be/UCEQmLxGiOk

- https://rumble.com/v3aqnxe-discover-the-surprising-impact-of-the-pushpull-view-of-supply-chain.html

Basically they are surely the terms that help us in a very decent way and that is the reason how we can get to know the ways for making a mark, agile business intelligence is a perfect source of improving overall and that gets counted.

great great i learned a lot

Hi , I am grateful to you also for complements.Hope to visit your website.

Hi, Thanks.