Abstract

A sustainable supply chain is measured by triple bottom line “Impact on people, profits and the planet”, which are the upstream components of the supply chain.This shift in paradigm usually reflects the understanding that the sustainable supply chains are profitable supply chains.Now supply chain sustainability can be measured and the supply-chains can take sustainability action plans.Distribution and manufacturing optimization and rationalization, the product design and the supplier etc are involved in terms of Supply Chain.If a company is able to choose between various suppliers, to implement sustainable strategies, they can use their purchasing power to push it’s suppliers with it’s green supply chain standards.They need to audit their supplier base and make sure that inputs from suppliers are of high quality, and the use of energy, water etc.Now the world’s largest retailer Walmart has widened its sights, building networks of employees, nonprofits, government agencies, and suppliers to “Green” it’s supply chains.

Keywords: Sustainability, Green supply chain, Profitable supply chain etc.

Article:

Introduction:

While discuss about Supply Chain Management Network Design the business issue of Supply Chain Sustainability is included by high level executives. Supply Chain Sustainability is affecting an organization’s logistic and Supply Chain Network in terms of environment, risk and cost of wastes. This is considered essential to deliver long term profitability instead of monetary cost, speed and value as dominant issue. There is a shift of paradigm from firm level to supply chain level competition and the challenge of adding sustainability targets into corporate behavior due to growing environmental and ethical awareness globally.

Definition of SSCM:

A truly sustainable supply chain would do no harm to natural or social systems, while producing profit over an extended period of time duration. If customers willing a truly sustainable supply chain continue to do business forever. A sustainable supply chain is measured by triple bottom line “impact on people, profits and the planet”, which are the upstream components of the supply chain.

The Sustainable Supply Chain perspective:

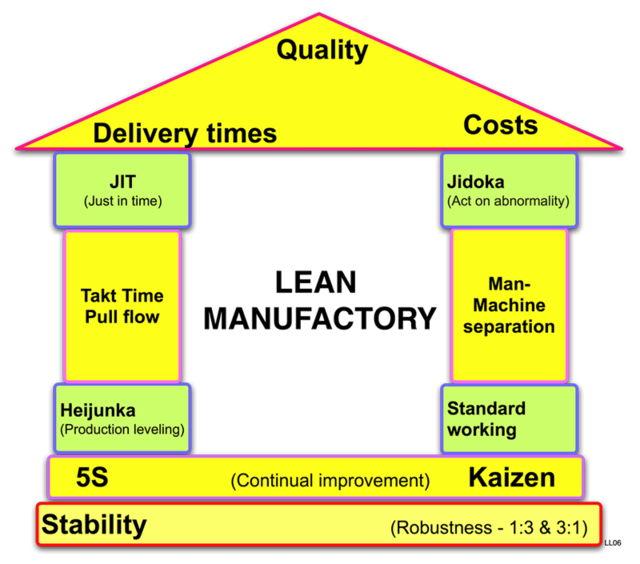

Supply Chains link input function with output functions. New challenges for environmentally friendly products are new measures of profitable logistical management in addition to traditional challenges, such as lowering costs, ensuring JIT in delivery and shorter transportation time. This shift in paradigm usually reflects the understanding that sustainable supply chains are profitable supply chains. While considering sustainability, some companies consider only their own business operations. Doing that they may not able to consider correct environmental costs .Also they may not able to remove waste from the supply chain. Now supply chain sustainability can be measured and supply chains can take sustainability action plans. Supply chains require collaboration for a successful sustainable supply chain. By collaboration supply chains can share distribution so that half empty vehicles should not be sent at the same destination. Also same address delivery can be made on the same truck. They can invest collaboratively for airships, canals etc. also in some way, which can reduce environmental impact and cost.

Sustainability Achievement Levels:

There are three levels of Sustainability Achievement criteria, which are achieved by an organization:

Level 1: Base Level

Majority organizations are in this level. Companies take simple measures such as switching lights and Computers off when left idle, employing greener forms of travel, recycling paper etc. Some also take initiatives to employ self-service technologies, as for example, teleconferencing, centralized procurement etc.

Level 2: Think sustainably

In this stage, companies start to realize the need to embed sustainability in Supply Chain Operations and assess their levels across local range of operations. Distribution and manufacturing optimization and rationalization, product design and supplier management etc are involved in terms of Supply Chain.

Level 3: Scientific sustainability

In this stage, companies use auditing and benchmarks, which provide framework for governing supply chain operations. This gives clarity to assess environmental impact on cost, agility and flexibility in the supply chain network. Supply chains recognize green operations as well as push operations to regulate both company and government operations.

Practical Application of Sustainability policies:

If a company is able to choose between various suppliers, to implement sustainable strategies, they can use their purchasing power to push it’s suppliers with it’s green supply chain standards. They need to audit their supplier base and make sure that inputs from suppliers are of high quality, and the use of energy, water etc. leading to less pollution, defects and over production by improving supply chain defects.

The Wal-Mart sustainability case:

For much of its history, Wal-Mart’s corporate management team toiled inside its “Bentonville Bubble,” narrowly focused on operational efficiency, growth, and profits. But now the world’s largest retailer has widened its sights, building networks of employees, nonprofits, government agencies, and suppliers to “green” its supply chains.[1] They are working and networking with other NGO’s and sustainability consultants to improve the sustainability aspects of their supply chain. They do not overburden their customers with sustainability related costs.

Conclusion:

A sustainable supply chain not only a green supply chain, it is profitable also. The greatest retailer Walmart is an example of a sustainable supply chain that is profitable also. Walmart does not do it in isolation. Its whole network becomes green and consumers get green products also.”Wal-Mart customers usually won’t pay extra for products just because they are better for the environment. But they will dig deeper for products that they believe are better for their families – such as organic cotton baby clothes.”[1]