Though there is inherent uncertainty about the future, a supply chain network risk analysis can be conducted; by using information available, the future business environment can be characterized. Network design decisions have a significant impact on performance of the supply chain. Though designing a supply-chain network can cut costs within a company, it is important to note the supply chain is not static but rather a continually improving model and adapt in response. The allocation of supply sources and markets to facilities has a significant impact on performance because it affects total production, inventory and transportation costs incurred by the supply chain to gratify customer demand. Good network design decisions increase supply chain profits, whereas poor network design hurts profit.

Category: Supply Chain Management

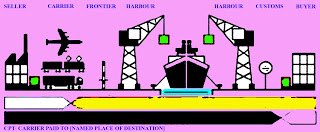

About procurement: Freight Prepaid related incoterm based on ICC amend. 2020.

Abstract “Freight Collect” & “Freight Prepaid” are two shipping terms, which show whether a consignee has the primary liability to the carrier for the shipping charges in a procurement process. EXW, FCA, FOB, FAS, etc Incoterm used for “Freight Collect” shipment. Now, we would like to discuss Incoterm which can be used for different “Freight Prepaid” shipments based on Incoterm of Sept 2019 published by ICC, also called 2020 amendment of incoterm. Keywords: International Procurement, Freight Prepaid, Freight collect, Incoterm, ICC, Amendment 2020. Article Introduction Transportation is one of the Drivers of the Supply Chain. The term Freight denotes transportation charges. The International Commercial Terms or INCOTERMS refers to whether the shipper/consignee […]

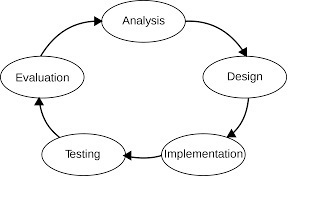

A discussion about basic steps of Leadership and Management of Procurement :

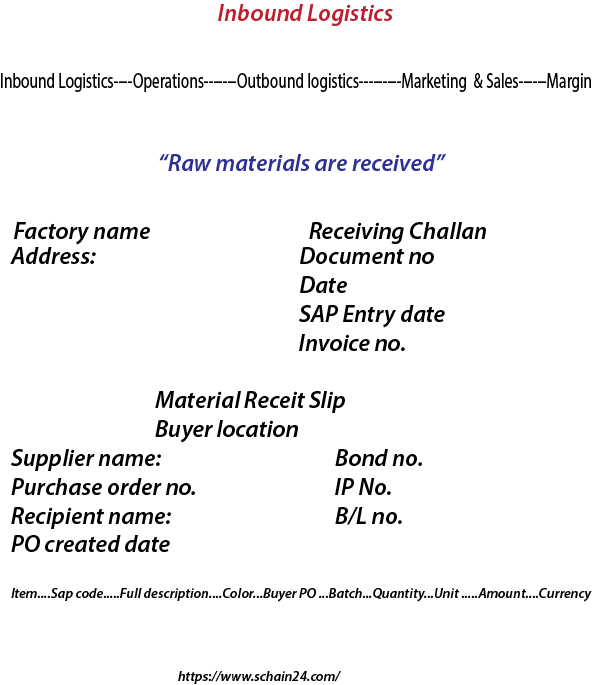

The company will qualify the suppliers to determine the best product for the business. It concretely defines the price, designations and terms and conditions of the product or accommodation and any supplemental obligations. The purchase order must be distributed, conventionally by fax, mail, personally, email or other electronic designates. The issues most often noted include payment dates, distribution times and work completion. Once the sending company distributes the product, the recipient accepts or rejects the items. Acceptance of the items obligates the company to pay for them. Three documents must match when an invoice requests payment – the invoice itself, the receiving document and the pristine purchase order.These include purchase records to verify any tax information and purchase orders to corroborate warranty information. The procurement department desires to offer simple, bottom line reporting to the higher management e.g., purchase fee index consistent with client/supplier etc. There should be a component, in keeping with which a much extra free time might be there to make a plan and do procurement capabilities and wrong things are discovered which need correction. Procurement and other capabilities: Procurement isn’t always very much an awful lot separate trouble with relation to other functions of a supply chain or commercial enterprise. it’s the solution to the question, why are we here? An imaginative and appropriate announcement narrates, what procurement branch of the firm expects to be its destiny? Eighty percent of one’s time to be spent with top 10-20% suppliers, take away “C” grade providers , broaden talent level, do the paper works , not an excessive amount of time spent for making plans.

About me

About I am, M. Ikramullah Sayeed, a Certified Supply Chain Manager and Logistics Professional, Writer, Translator, Editor, Team Builder, Blogger, and a son and a father. I am working with a multinational group of company. Description I have long and extensive professional experience in the field of Logistics and Supply Chain area in manufacturing and 100% export oriented industry, also […]

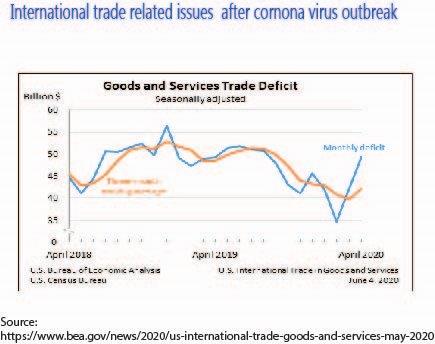

Covid-19 : Her affects on global economy and supply chain

Society, businesses and governments can all be remodeled in the aftermath of the coronavirus happening, and that we hope, towards a lot of sustainable society, thus, students and managers ought to plan to think about this transformation through a positive lens so as to boost supply chains to produce high worth and even a lot of outstanding services to society, since it’s currently extravagantly clear that supply chains are the veins of the whole economy. In line with UNEC for Latin America estimate, the pandemic-induced recession might leave 14–22 million of individuals in extreme economic condition in Latin America than the scenario while not the pandemic. Lloyd’s of London has calculated that the worldwide insurance trade has to absorb losses of US$204 billion, more extraordinary than the losses from the 2017 Atlantic cyclone season and 9/11, suggesting the COVID-19 pandemic is possibly costliest disaster ever in human history. Governments are possibly to take a position and regulate “key supply chains”, like pharmaceutical, personnel protecting instrumentation and agro-food chains so as to make sure national food security. As of 6 July 2020, over 11.4 million cases of COVID-19 are reported in addition for 188 countries and territories, leading to over 533,000 deaths. On a daily basis a lot of cases are reported, and new countries enter the World Health Organization’s (WHO) list of areas wherever the virus has been reported suggested preventive measures embrace hand washing, covering one’s mouth once coughing, maintaining distance from others, sporting a mask at public settings, and observation and self-isolation for people that suspect they’re infected. The COVID-19 pandemic, referred to as the coronavirus pandemic, is in progress as the global pandemic of coronavirus illness 2019 (COVID 19), caused by severe acute respiratory syndrome coronavirus as a pair of (SARS CoV 2).

Keywords: covid-19, global supply chain, supply chain sustainability, economy.

A Lean Logistic Control System : Kanban

To run a production system as a whole and to promote improvement kanban is used as tool. The Kanban system was implemented in 1953 in Toyota Company manufacturing process. Those signals are tracked by replenishment cycle, so that suppliers and buyers notice it. They observed that they can view a process as being a customer and proceeding process as a store. Signboards were used to give expression of shipping at the store. Kanban is part of a system where “Pull” comes from the demand. According to Taiichi Ohno , must follow strict rules to be effective, also need close monitoring of products ,so that products with defect should not be sent to subsequent process, produce exact quantity; the process should be tuned finely and rationally.