In drop-sip model, product is shipped directly from manufacturer end bypassing a retailer. Benefits of aggregation can be achieved, if the manufacturer can keep some of its inventory at the retailer end on and as needed basis. In addition, drop-shipping offers manufacturer an opportunity to postpone customization until the customer has placed order finally. Response times tend to be long, because the order has to be transmitted from retailer to the manufacturer and shipping distance are generally longer from the manufacturer’s centralizing site. Order visibility is very important in the context of manufacturer storage, because two stages in the supply chain are involved in every customer order. But a manufacturer storage network is likely to have difficulty handling returns, so that customer satisfaction may be hurt. Because, each order may involve more than one manufacturer.

Keywords: drop-shipping.

Tag: Supply Chain Management Network Design

A discussion about International export and outbound logistics of goods

In the export trade, goods and services are sold and shipped out of the jurisdiction of the country and customs authorities. While export to developed countries, Bangladesh gets some tariff facilities. It is nothing but helping the developing countries in export trade and industrialization, on the other hand, they regulate some products to enter their country at a lower price. Currently, Bangladesh is enjoying tariff-free market access for 90 per cent to 100 per cent products in all the developed countries except the United States. Tariff-free and low-tariff market access facilities in the developed and some developing countries immensely benefited Bangladesh. Bangladesh High Commissioner to Ottawa wrote that quality of Bangladesh’s apparel products as well as efficient supply-chain mechanism has largely contributed to doubling bilateral trade in a decade.

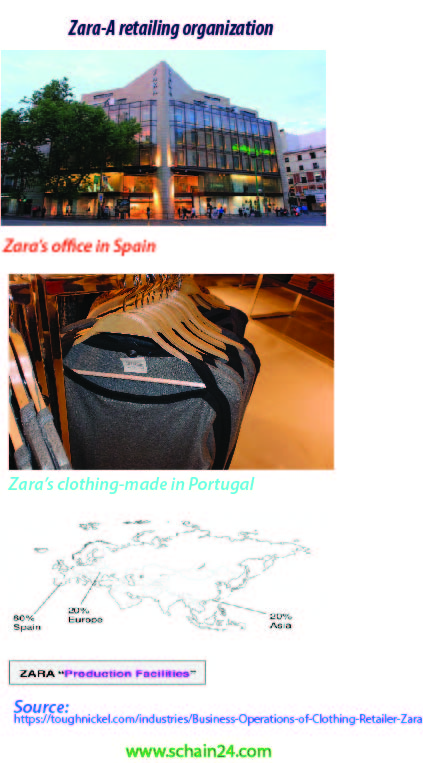

Zara, a Retailing Organization: An SCM Case Analyzed ।

The retailing organization Zara has suppliers from about 50 countries. Zara is called “Fast fashion” in a segment of the market. Following things in Zara’s ICT try to seamlessly coordinate between organizations and enhance supply chain integration. The organization’s technology improves operational responsiveness to customers, at the same time reduces cost. her main strategy is to answer quickly to consumer demand and anticipate consumer trends through IT and human resources. Zara continues to update information based on checking with store managers using PDA and updating customers’ responses.

Facts of Transportation in a Logistical perspective: Highlights on some Bangladesh issues

Package carriers, such as DHL, FedEx, UPS, etc. usually carry letters and other small cargo weighing below 150 pounds using air, Truck, and rail to carry time-sensitive smaller packages. Companies use air cargo carriers for larger cargo and package carriers for more time-sensitive smaller cargo. A carrier takes investment decisions regarding their equipment; Shipper in contrast uses transportation to minimize total cost, while providing an appropriate level of responsiveness to the customers. The Key issues air carriers usually face include identifying the location and a number of hubs, assigning planes to routes, and maintaining a schedule of planes and crews, also available at different prices. The effectiveness of any mode of transportation is affected by the carrier as well as infrastructure and transportation policies, e.g., an airline’s goal is to maximize the daily flying time of a plane and generated revenue per trip. Supply Chains using modes of transportation, such as air, package carriers, trucking, rail, water, pipelines, intermodal, etc. The cargo moves from the factory premises to the port in a truck or multi-modal movement of truck and container on the rail. The shipper requires the movement of products from one point to another in a Supply Chain and Carrier is the party who moves the cargo. AI algorithms can optimize routes for each autonomous vehicle in real-time, based on traffic data, road conditions, and other factors. AI algorithms can mine historical and real-time traffic data to create predictive models to anticipate traffic congestion and accidents. AI will manage the optimum distance between vehicles, maintain constant communication between vehicles, and plan the formation of vehicle clusters to ensure consistent traffic flow and avoid bottlenecks. Air carriers usually carry below 500 pounds, high-value, and lightweight products.

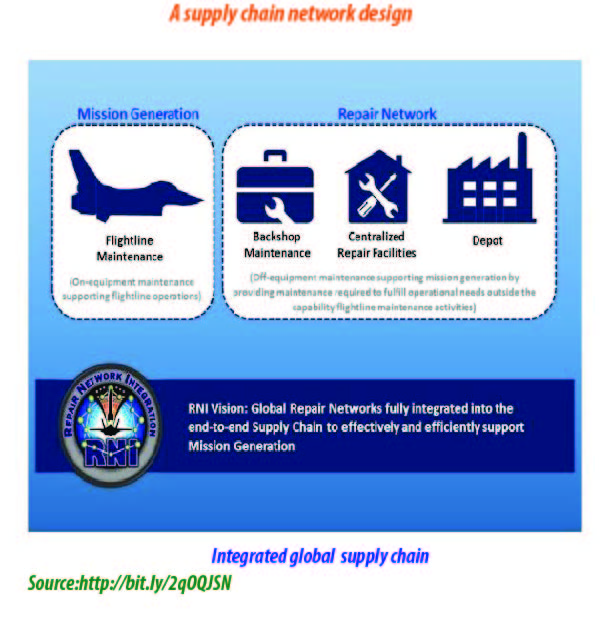

Role of Network Design in the supply chain: A brief description

Though there is inherent uncertainty about the future, a supply chain network risk analysis can be conducted; by using information available, the future business environment can be characterized. Network design decisions have a significant impact on performance of the supply chain. Though designing a supply-chain network can cut costs within a company, it is important to note the supply chain is not static but rather a continually improving model and adapt in response. The allocation of supply sources and markets to facilities has a significant impact on performance because it affects total production, inventory and transportation costs incurred by the supply chain to gratify customer demand. Good network design decisions increase supply chain profits, whereas poor network design hurts profit.

5 Reason your Enterprise Need Supply Chain Integration

Supply Chain Integration help in reducing product delays by improving the efficiency of the supply chains. The product delays are largely a by-product of mismatch in information and dis-coordination between the delivery, warehousing, and trading partners. This brings visibility to all parts of the supply chain and helps in giving adequate information about each step that ensures compliance, adherence to the safety standards and product quality. This helps in making supply chain agile and scale-able and gives confidence to the stakeholders to make sure the best practices are implemented at all the level of supply chain operations.

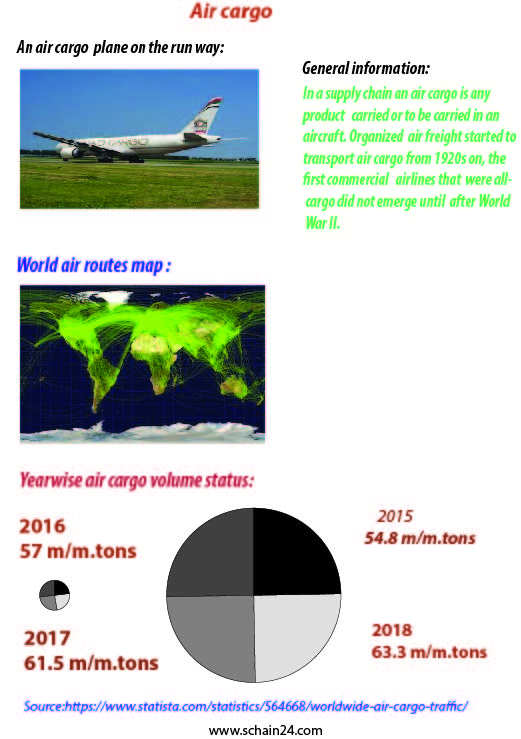

A discussion about air freight mode of transportation in a supply chain.

Abstract: In a supply chain an air cargo is any product carried in an aircraft. Organized air freight started to transport air cargo from the 1920s on, the first commercial airlines that were all-cargo did not emerge until after World War II. In 1945, 57 airlines formed the International Air Transport Association. The three primary air shipping options are next […]