Abstract

Supply Chain Integration helps in reducing product delays by improving the efficiency of the supply chains. The product delays are largely a by-product of a mismatch in information and coordination between the delivery, warehousing, and trading partners. This brings visibility to all parts of the supply chain and helps in giving adequate information about each step that ensures compliance, adherence to safety standards, and product quality. This helps in making the supply chain agile and scaleable and gives confidence to the stakeholders to make sure the best practices are implemented at all levels of supply chain operations. Also, all the operational data is centralized through which an enterprise can ensure that supply chain operations are compliant and adhere to the standard practices at all the steps and thus maintain the desired quality levels. An integrated supply chain provides clear communication to all the functions and makes sure there is better collaboration and planning at all levels. An integrated supply chain centralizes the complete operation of the supply chain and automates the workflow between various functions Now all the information is quickly accessible to all the stakeholders.

Keywords: Supply chain integration, visibility.

Introduction

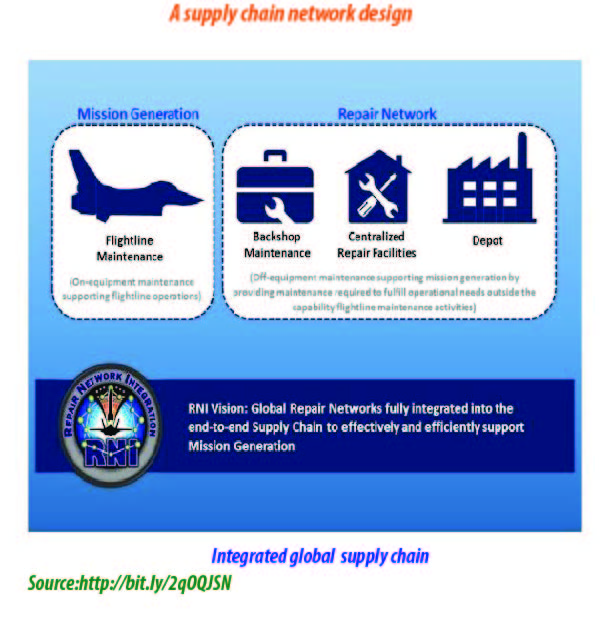

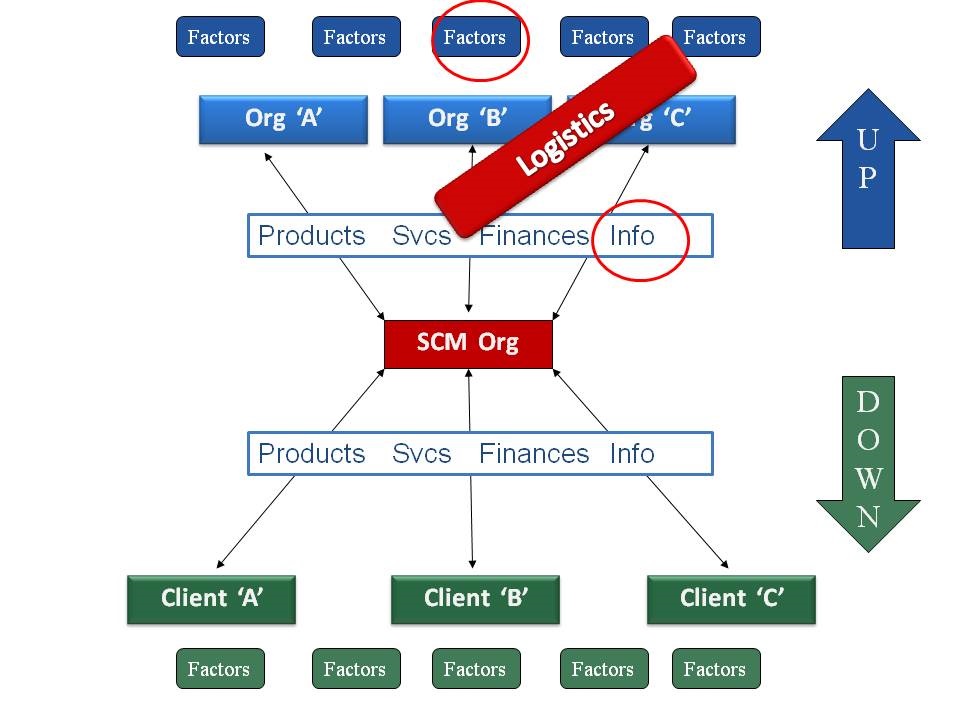

Today’s supply chains are getting complex because of growing vendors based out of different countries, and evolving geo, political, and economic trends. As per Gartner, the supply chain management (SCM) market will exceed $13 billion in total software revenue by the end of 2017 to exceed $19 billion by 2021, as software as a service (SaaS) enables new revenue opportunities. To optimize supply chain operations, all the associated functions such as suppliers, transportation, manufacturing hubs, production levels, warehouses, distributors, etc. need to be integrated. There is a need for specialized supply chain integration solutions.To gain a competitive edge over competitors, more and more enterprises are looking to deploy digital technologies in their underlying business, and supply chain management becomes their top priority to start with. This blog will throw some light on the benefits of supply chain integration.

Transparency

An integrated supply chain centralizes the complete operation of the supply chain and automates the workflow between various functions. Now all the information is quickly accessible to all the stakeholders. This brings visibility to all parts of the supply chain and helps in giving adequate information about each step that ensures compliance, adherence to safety standards, and product quality.

Business Intelligence

Supply chain integration provides real-time business intelligence. It makes use of historical data and provides analytical insights for determining product demand and predicting the forecast. It helps organizations to charter out their MPS (Master Production Schedule) based on the real-time intelligence available and optimizes the materials, inventory, production schedules, and storage location accordingly. This directly leads to better planning and forecasting along with improved relations both with the vendors and distributors.

Collaboration

Supply Chain Integration helps in reducing product delays by improving the efficiency of the supply chains. The product delays are largely a by-product of a mismatch in information and dis-coordination between the delivery, warehousing, transportation, and trading partners. An integrated supply chain provides clear communication to all the functions and makes sure there is better collaboration and planning at all levels.

Flexibility

An integrated supply chain uses the cloud-based platform which makes it highly scalable and flexible. The ever-changing business requirements can be incorporated into a live supply chain making no significant investments in any hardware or software requirements. This helps in making the supply chain agile and scale-able and gives confidence to the stakeholders to make sure the best practices are implemented at all levels of supply chain operations. It also empowers and prepares them to quickly respond to business requirements for any internal or external events.

Quality Control

Quality control remains the biggest threat to supply chain operations. It denotes the sensitive side of an enterprise. Supply chain integration gives organizations the utmost control over their operations. The solution enables them to view, track and change the movement of material, inventory, transportation, storage, and production schedules as per the market demands. Also, all the operational data is centralized through which an enterprise can ensure that supply chain operations are compliant and adhere to the standard practices at all the steps and thus maintain the desired quality levels. This improves the efficiency of the supply chain and helps in attaining supply chain sustainability.

Conclusion

Enterprises implementing integrated supply chains will have an undisputed advantage over the contemporaries and it gives an impetus to their digital transformation pursuits. A supply chain integration solution provides great benefits ranging from increased efficiencies, to increased business intelligence to reduced costs, etc. Not just only enterprises, an integrated supply chain can also benefit the trading partners to feel visibility in the complete supply chain operations. The right integration solution ensures to take all the stakeholders in the supply chain ecosystem together to build future-ready digital enterprises.

Further reading:

1.Fawcett.Stanley E., Magnan.Gregory M.(2002).”The rhetoric and reality of supply chain integration“,International Journal of Physical Distribution & Logistics Management, ISSN: 0960-0035.