Abstract

The design decisions determine the configuration and set constraints within which other supply chain drivers can be used either to decrease cost or to increase responsiveness. Mapping denotes accumulating information about your suppliers, their own suppliers, and the people who work in your supply chain to engender an ecumenical map of your supply network. Supply-chain-management software (SCMS) is the software tools or modules used in executing transactions, managing supplier relationships, and controlling associated business processes.

Keywords: Supply Chain, Supply chain mapping.

Introduction

The supply chain is nothing but an entire system of engendering and distributing a product or accommodation, from sourcing the raw materials to the final distribution of the product or accommodation to culminate users. In commerce, a supply chain is a network of facilities that procure raw materials, transform them into intermediate goods, and then final products to customers through a distribution system. It refers to the network of organizations, people, activities, information, and resources involved in distributing a product or service to a consumer.

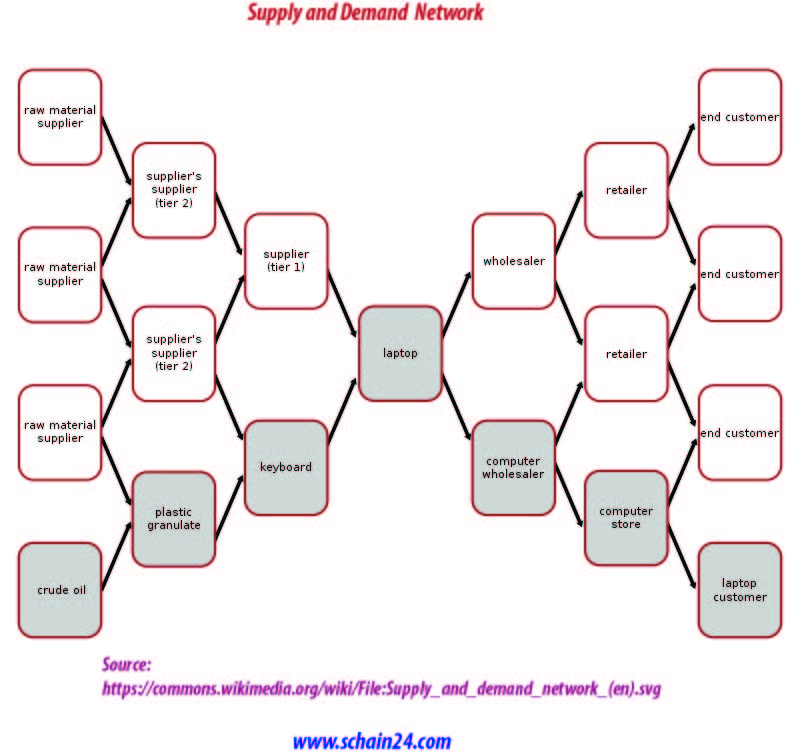

A typical Supply chain

A chain is authentically an involute and dynamic supply and authoritatively mandate network. A typical supply chain commences with the ecological, biological, and political regulation of natural resources, followed by the human extraction of raw material, and includes several engendering links such as component construction, assembly, and merging afore moving on to several layers of storage facilities of an ever-decrementing size and increasingly remote geographical locations, and conclusively reaching the consumer. to the way supply networks authentically operate. As a component of their efforts to demonstrate ethical practices, many astronomically immense companies and ecumenical brands are integrating codes of conduct and guidelines into their corporate cultures and management systems. A lack of transparency in the supply chain can bar consumers from the erudition of where their purchases originated and facilitate gregariously irresponsible practices. In 2018, the Loyola University Chicago`s Supply and Value Chain Center found in a survey that 53% of supply chain professionals considered ethics to be “astronomically” paramount to their organization. Supply-chain managers are under constant scrutiny to secure the best pricing for their resources, which becomes an arduous task when faced with the intrinsic lack of transparency.

Mapping a Supply chain

Mapping out a supply chain is one of the critical steps in performing an external analysis in a strategic orchestrating process. Mapping denotes accumulating information about your suppliers, their own suppliers, and the people who work to engender an ecumenical map of your supply network. This information can be held in a single data platform for ease and to facilitate analysis. The consequentiality of limpidly laying out the supply chain is that it avails a company to define its own market and decide where it wants to be in the future. In developing corporate-level strategies, a company often needs to make decisions on whether to operate a single line of business or enter into other cognate or unrelated industries. Each stage of a chain is essentially a different industry, for example, raw material extraction and manufacturing. It enables a company to understand others that are involved in each of the stages and thereby provides some insights into the attractiveness or competitiveness in industries the company might want to enter in the future.

Supply Chain Network design

Network design decisions have a significant impact on the performance of the supply chain. These decisions determine the configuration and set constraints within which other drivers can be used either to decrease cost or to increase responsiveness. Facility location decisions have a long-term impact on performance because it is very costly to shut down a facility or move it to a new location. Capacity allocation decisions also have a significant impact on supply chain performance. Although capacity allocation can be altered more easily than location, capacity decisions tend to stay in place for several years. Allocating too much capacity to a location results in poor utilization, and resultant higher costs. Allocating too little capacity results in poor responsiveness if demand is not satisfied or high cost if demand is filled from distant facilities. The allocation of supply sources and markets to facilities has a significant impact on performance because it affects total production, inventory, and transportation costs incurred to gratify customer demand. Good network design decisions increase profits, whereas poor network design hurts profits.

Supply chain security

Supply-chain-management software (SCMS) is the software tools or modules used in executing supply chain transactions, managing supplier relationships, and controlling associated business processes. It maximizes the efficiency of business activities that include planning and management of the entire supply chain. It helps businesses in product development, sourcing, production, and logistics by automating operations. In this way, it increases the physical flow of business as well as the informative flow. The entire business benefits with higher performance, greater cost-efficiency, and thus increased efficiency. We should not use the software if not required. Especially, freeware, browser extensions, and plugins are a great source of cyber-related attacks. We should check first if we need it. Need to use Intrusion Detection Systems (IDS) and Intrusion Prevention Systems (IPS) systems to detect exceptions in our orders. Patch control is also essential to avoid such attacks.

CSR

Finally, they highlight that collaboration with local partners, across the industry, and with universities is crucial to successfully managing social responsibility in supply chains. This accident of workers at Rana Plaza also highlights the need to improve worker safety standards in organizations. Hoi and Lin (2012) note that corporate social responsibility can influence the enacting of policies that can improve occupational safety and health management in organizations.

Conclusion

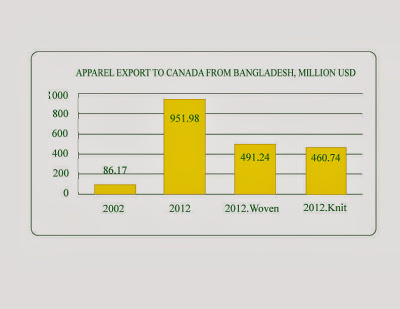

There are different types of supply chains such as Food, Cold chain, apparel, agro chain, etc. In March 2022 the Commission noted, “the need for EU agriculture and food supply chains to become more resilient and sustainable“.

References

- Hayes, Adam. “Supply Chain”. Investopedia. Retrieved 15 September 2022.

- https://corporatefinanceinstitute.com/resources/management/supply-chain/

- https://commons.wikimedia.org/wiki/File:Supply_and_demand_network_(en).svg

- https://www.smartsheet.com/content/process-map-templates

- European Commission, Commission acts for global food security and for supporting EU farmers and consumers, published 23 March 2022, accessed 26 April 2022

- https://youtu.be/9WPGLJBRsYg