Abstract

Digital supply chain risk due to the potential for Internet of Things (IoT) security vulnerabilities, which arise when assets and machines share data via sensors and software, the digital supply chain may be exposed to danger. Stages of digital supply chain management involve planning out processes and inventory before advancing to order management.

Keywords: digital supply chain

Introduction

Digital supply chain management is included in the electronic technologies and tools organizations use to support their supply chain from end to end. Automation competencies and digital tools enable organizations to reduce their use of paper, eliminate manual processes, and decrease the need for information requests since all vendor and buyer data is hosted in one location. The objective of digital supply chain management is to holistically manage your orders, invoices, and supplier and buyer relationships, all on a digital stage that is easy to access for all involved parties. With enhanced insights and data, digital supply chain management platforms offer a complexity of information on performance, requirements, and overall supply chain dynamics that leaders can use to make knowledgeable decisions.

A traditional supply chain vs. digital supply chain

A typical supply chain commences with the ecological, biological, and political regulation of natural resources, followed by the human extraction of raw material, and includes several engendering links such as component construction, assembly, and merging afore moving on to several layers of storage facilities of an ever-decrementing size and increasingly remote geographical locations and conclusively reaching the consumer.

In traditional supply chains, humans are making decisions based on machine inputs, while in digital supply chains, machines are driving the decisions with human oversight.

Digital supply chain risk

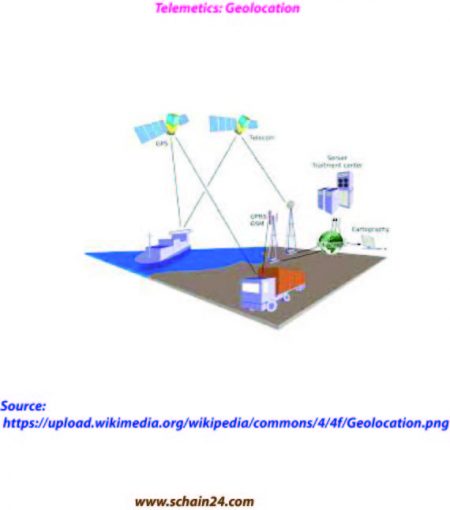

Due to the potential for Internet of Things (IoT) security vulnerabilities, which arise when assets and machines share data via sensors and software, the digital supply chain may be exposed to danger. This can cause malicious actors to alter data or program devices to behave in a dangerous manner, and updating a supply chain necessitates capital expenditures. Stakeholders in the supply chain might also require data that differs from what manufacturers require, such as throughput data that is so low that merchants cannot use it to determine whether manufacturing is on time.

Stages of digital supply chain

Digital supply chain management involves planning out processes and inventory before advancing to order management. The sourcing stage involves classifying vendors and suppliers for goods and services necessary for order completion. The delivery stage involves more direct interaction and appointment with customers, and the return stage involves relationship management. Digital supply chain management tools help to make this stage more efficient by granting both parties access to the necessary information and facilitating a space for open and honest communication.

Challenges of digital supply chain

Digital supply chain management strategies are becoming increasingly important as business operations expand globally and organizations embrace and implement digital tools in their existing processes. Digital supply chain management provides many benefits for organizations, such as enhanced collaboration, automation capabilities, improved data accuracy, and better data analytics. It also reduces the likelihood of departments undergoing a “data silo effect” by sharing transaction information among internal and external teams. Additionally, digital supply chain management tools have features that can spot problem patterns, identify bottlenecks, pinpoint savings and cost-reduction opportunities, watch for imminent and future risks, and enable real-time transactional reporting.

Organizations may face hurdles to implementing a digital supply chain management system, such as low acceptance initially, lack of cooperation, and siloed departments. These challenges can be overcome by offering support and training to teams and suppliers, creating a resilient and efficient integration.

Advantages of digital supply chain

Digital supply chain management strategies are becoming increasingly important as business operations expand globally and organizations embrace and implement digital tools in their existing processes. Digital supply chain management provides many benefits for organizations, such as enhanced collaboration, automation capabilities, improved data accuracy, and better data analytics. It also reduces the likelihood of departments undergoing a “data silo effect” by sharing transaction information among internal and external teams. Additionally, digital supply chain management tools have features that can spot problem patterns, identify bottlenecks, pinpoint savings and cost-reduction opportunities, watch for imminent and future risks, and enable real-time transactional reporting.

Digital transformation

Digitization in the supply chain has become increasingly important due to the pandemic, providing access to real-time information, increased visibility into data and transaction records, and increased efficiency. With the support of a digital platform, businesses can speed up their order process and delivery times, making suppliers and customers more satisfied.

Future of digital supply chain

Companies committed to excellence in supply chain execution should be moving toward a digital strategy. McKinsey noted that there is not yet a “Toyota Way” of the digital supply chain, but 66% of supply chain professional respondents to a survey showed that implementing new technologies and capabilities was a top priority. Technology is the No. 1 area where CFOs are open to new spending, and digital supply chains can reduce costs, boost EBITDA, increase revenue, and increase customer service.

Conclusion

The digital supply chain is nothing but a transformation of the supply chain management so that it can be visualized and more result oriented. But it does not look the same as before. It can support the consumer more.

References:

- https://www.netsuite.com/portal/resource/articles/erp/digital-supply-chain.shtml

- https://tradeshift.com/solutions/digital-supply-chain-management/

- https://www.schain24.com/2022/12/01/supply-chain-how-to-define-the-term-and-the-process-in-general/#ixzz7x8I5R400

- https://youtu.be/HkHwu0VKrIk