A study supports the concept of an analytics culture built on advanced data management processes, technologies, and talent. SCAG can strengthen firms’ core features, such as ambidexterity, adaptability, and swiftness, enabling them to upgrade their performance in terms of sales, profit, and return on investment. SCAC can improve end-to-end supply chain productivity and eliminate market fragmentation. The study finds a significant positive relationship between SCAC and firm performance, with a mediating effect on supply chain agility. This could guide managers in investing in SCAC and considering complementary assets like supply chain agility to achieve a continued competitive advantage. SCAC can accelerate FPER by establishing robust agility in operations.

Search Results for: supply chain planning

Weather impacts on supply chain management: An analysis

Supply chains engender great opportunities for the weather forecasting industry to advance. Those who can utilize these kinds of forecasting, are beneficial to some extent and preserved from loss of weather disruptions. On one hand, the impact of weather in many cases increases the cost of the supply chain, on the other hand, it decrements the visibility of the supply chain due to inclement weather. Various weather stations measure weather data such as rainfall, shipping, etc. Weather cognate courses are being evolved for supply chain managers to tackle weather disruption issues well. The other utilization of weather reports from third-party companies can help forecast early solutions and point out the affected areas.

Supply Chain Management and its Drivers:

Abstract The logistical drivers are facilities, inventory, and transportation. Inventory denotes all raw materials, WIP, and finished goods in a supply chain. On the other hand, transportation involves moving inventory from point to point. Information is data about facilities, inventory, transportation, costs, prices and customers throughout the supply chain, also gives shipping options to managers. Pricing drivers determine the price […]

A brief discussion about digital supply chain management

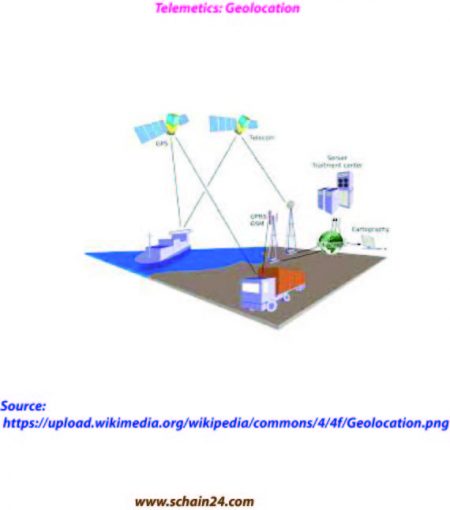

Digital supply chain risk due to the potential for Internet of Things (IoT) security vulnerabilities, which arise when assets and machines share data via sensors and software, the digital supply chain may be exposed to danger. Stages of digital supply chain management involve planning out processes and inventory before advancing to order management.

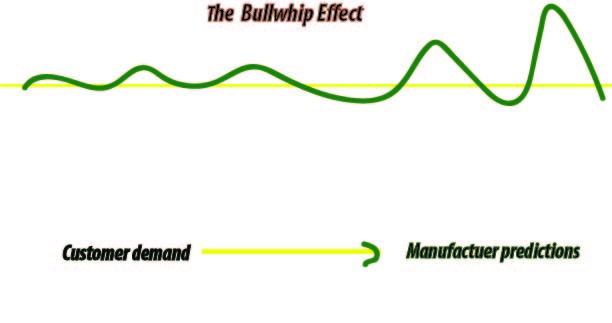

A discussion about lack of supply chain coordination and the bullwhip effect

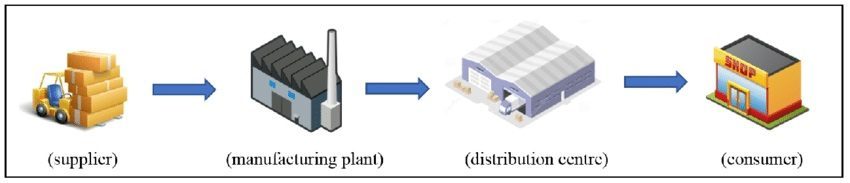

In SCM, a supply chain manager coordinates the logistics of all the aspects of the supply chain which consists of five parts: the plan or strategy, the source of raw materials and services, manufacturing, i.e., productivity and efficiency, delivery and logistics, the return system for defective and unwanted goods etc. The phenomenon that fluctuation in orders increases as one moves up the supply chain from retailers to wholesalers to manufacturers to suppliers is referred to the bullwhip effect. Managers can help achieve coordination in supply chain by aligning goals and incentives across different functions and stages of the supply chain. When supply chain moves from retailers to wholesalers to manufacturers to suppliers, the bullwhip effect occurs. It results in different stages optimizing local objectives instead of total supply chain profits. The bullwhip effect results in costs in the supply chain and decrease in levels of customer service.

Supply chain: how to define the term and the process in general

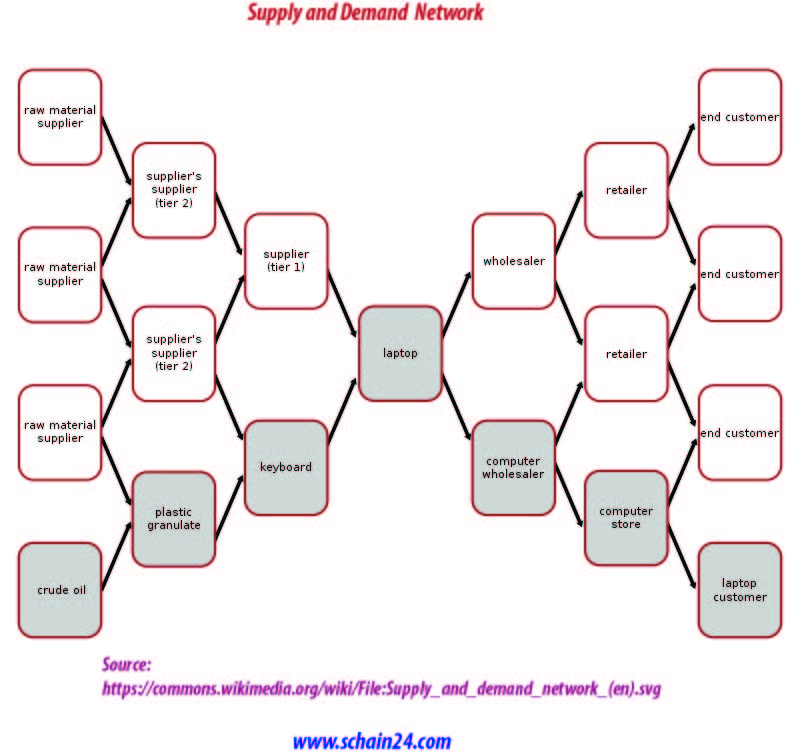

The design decisions determine the supply chain configuration and set constraints within which other supply chain drivers can be used either to decrease supply chain cost or to increase responsiveness. Mapping your supply chain denotes accumulating information about your suppliers, their own suppliers, and the people who work in your supply chain to engender an ecumenical map of your supply network. Supply-chain-management software (SCMS) is the software tools or modules used in executing supply chain transactions, managing supplier relationships and controlling associated business processes.

What are the Roles of Network Design in the Supply Chain Management?

Though there is inherent uncertainty about the future, a supply chain network risk analysis can be conducted; by using information available, the future business environment can be characterized. Network design decisions have a significant impact on performance of the supply chain. Though designing a supply-chain network can cut costs within a company, it is important to note the supply chain is not static but rather a continually improving model and adapt in response. The allocation of supply sources and markets to facilities has a significant impact on performance because it affects total production, inventory and transportation costs incurred by the supply chain to gratify customer demand. Good network design decisions increase supply chain profits, whereas poor network design hurts profit.